Risk of ecv

What Is It, Procedure, Risks, Labor, & More

External Cephalic Version: What Is It, Procedure, Risks, Labor, & MoreMedically reviewed by Holly Ernst, PA-C — By Becky Young on April 12, 2018

What is external cephalic version?

An external cephalic version is a procedure used to help turn a baby in the womb before delivery. During the procedure, your healthcare provider places their hands on the outside of your belly and attempts to manually turn the baby.

This procedure may be recommended if your baby is in a breech position. This means that their bottom or feet are pointing down toward the vagina, and their head is at the top of your uterus, near your rib cage. A vaginal breech birth is more complicated than a birth where the baby is head down, so it’s preferable that baby is head down before labor starts.

Some women opt to birth their babies via cesarean delivery (C-section) rather than attempt a vaginal breech birth if they’re near or past their estimated due date and the baby still hasn’t turned.

Is it safe?

Most women who are 37 weeks pregnant with a baby in the breech position are candidates for an external cephalic version. The procedure has been found to be successful in turning these babies into a head-down position in around 50 percent of cases. Since breech babies often result in C-sections, a successful external cephalic version may reduce your need for this type of delivery, which is considered an abdominal surgery.

There are some situations in which your healthcare providers may suggest an external cephalic version isn’t right for you. This procedure may not be right for you if:

- you’re already in labor or experiencing any vaginal bleeding

- you’ve had any issues with your placenta during the pregnancy

- there are signs of or concerns for fetal distress

- you are pregnant with more than one baby, such as twins or triplets

- you have any structural abnormalities in your uterus, like large fibroids

Your healthcare provider may also advise against the procedure if you’ve had a previous C-section, your baby is suspected to be larger than average, or you have low or high levels of amniotic fluid. These risk factors are based upon clinical opinion, so you should talk with your healthcare provider to see what they recommend based on your individual pregnancy.

These risk factors are based upon clinical opinion, so you should talk with your healthcare provider to see what they recommend based on your individual pregnancy.

You discuss external cephalic version between 34 and 37 weeks of pregnancy with your doctor if your baby is noted to be breech. Babies often turn on their own before 34 weeks, so there is no need to attempt the procedure earlier in the pregnancy.

The procedure does increase your risk for premature labor and fetal distress. For that reason, most healthcare providers recommend waiting until you’re at term, or 37 weeks pregnant, to attempt this procedure. That reduces risk for complications in your baby if you do need to deliver shortly following the procedure.

You can also talk with your doctor about waiting past 37 weeks, as the baby may spontaneously turn to a head-down position.

The most common risk with an external cephalic version is a temporary change in your baby’s heart rate, which occurs in about 5 percent of cases. Serious complications are extremely rare but can include the need for emergency C-section, vaginal bleeding, loss of amniotic fluid, and umbilical cord prolapse.

Serious complications are extremely rare but can include the need for emergency C-section, vaginal bleeding, loss of amniotic fluid, and umbilical cord prolapse.

What to expect during the procedure

The procedure will normally be performed by an obstetrician. During an external cephalic version, your doctor will place their hand on your belly to physically push the baby into the optimal position. The procedure usually takes around 5 minutes and your baby’s heart rate will be monitored before, during, and after the procedure. If your doctor suspects your baby isn’t responding well to the procedure, it will be stopped.

Many women report that the procedure is uncomfortable, but medications can be used to reduce the amount of pain felt. Using certain medications during the procedure may also increase the chances of successfully turning the baby. This may be because the medication helps your muscles and uterus relax, allowing the healthcare provider to successfully turn the baby more easily.

How will this procedure affect labor and delivery?

If an external cephalic version is successful, then most of the time labor progresses in a regular way following the procedure. The procedure doesn’t generally affect the length of your labor.

There is a small risk that the procedure will rupture membranes e. This can mean that you will begin labor earlier than you might otherwise have done, and your contractions may be more intense from the beginning of labor instead of building in intensity as the labor progresses.

If the procedure is unsuccessful and your baby remains in the breech position, you could opt for a C-section or choose to attempt a vaginal breech delivery.

One of the main risks involved with a vaginal breech delivery is that your baby’s head could become trapped in the birth canal. The other serious concern is umbilical cord prolapse. With umbilical cord prolapse, the umbilical cord leaves your body before your baby. That increases the risk of the cord becoming compressed during delivery, which cuts off the baby’s supply of oxygen and nutrients.

Both of these complications are a medical emergency. Evidence does show an increased risk of perinatal mortality in planned vaginal breech birth as opposed to a C-section with breech presentation.

Are there other ways to turn the baby?

There are a number of different exercises you can try to attempt to turn your baby from the breech position, though these haven’t been proven in studies to be effective in spontaneously turning the breech baby. Always talk to your healthcare provider before trying these exercises to make sure that they are safe for your pregnancy.

Hip tilt

- Lie on the floor in front of a sofa or chair, with your feet on the sofa or chair. Place cushions under your hips to offer additional support. Your hips should be elevated about 1.5 feet above your head, and your body should be at a 45-degree angle.

- Hold this position for 10 to 15 minutes, three times a day. It’s best to do this when your baby is active.

Pelvic rotations

- Stand or sit on an exercise or birthing ball.

- Once you are in position, gently rotate your hips clockwise in a circular movement. Repeat 10 rotations.

- Switch directions, rotating your hips counterclockwise for 10 rotations.

- Repeated three times a day

Rocking back and forth

- Place your hands and knees on the floor.

- Keeping your hands and knees in place, gently rock your body back and forth.

- Do this for 15 minutes. Repeat up to three times a day.

Walk or swim

- Walk, swim, or engage in another low-impact exercise.

- Do this for 30 minutes a day. Staying active may help your baby move out of the breech position.

The takeaway

It’s recommended that an external cephalic version be offered to all women who have a baby in breech position at or close to term, where there are no other complications. The procedure has been shown to be successful in around half of all cases and may lower the likelihood that a C-section will be needed. There are some possible risks, so be sure to discuss the risks and benefits with your healthcare provider before moving forward with this procedure.

There are some possible risks, so be sure to discuss the risks and benefits with your healthcare provider before moving forward with this procedure.

Last medically reviewed on April 12, 2018

- Parenthood

- Pregnancy

- 3rd Trimester

How we reviewed this article:

Healthline has strict sourcing guidelines and relies on peer-reviewed studies, academic research institutions, and medical associations. We avoid using tertiary references. You can learn more about how we ensure our content is accurate and current by reading our editorial policy.

- Berhan Y, et al. (2015). The risks of planned vaginal breech delivery versus planned caesarean section for term breech birth: A meta-analysis including observational studies. DOI:

10.1111/1471-0528.13524 - Grootscholten K, et al. (2008). External cephalic version-related risks: A meta-analysis [Abstract]. DOI:

10. 1097/AOG.0b013e31818b4ade

1097/AOG.0b013e31818b4ade - Kathpalia BSK, et al. (2012). Outcome of external cephalic version in breech presentation. DOI:

10.1016/S0377-1237(12)60036-7 - Kuppens SM, et al. (2017). Fetal heart rate abnormalities during and after external cephalic version: Which fetuses are at risk and how are they delivered? DOI:

10.1186/s12884-017-1547-6 - Lim PS, et al. (2014). Successful external cephalic version: Factors predicting vaginal birth. DOI:

10.1155/2014/860107 - Wang Z-H, et al. (2017). Remifentanil analgesia during external cephalic version for breech presentation in nulliparous women at term: A randomized controlled trial. DOI:

10.1097/MD.0000000000006256 - What happens if your baby is breech? (2017).

nhs.uk/conditions/pregnancy-and-baby/breech-birth/

Share this article

Medically reviewed by Holly Ernst, PA-C — By Becky Young on April 12, 2018

related stories

What Is Back Labor and What Causes It?

Can You Turn a Transverse Baby?

What You Need to Know If Your Baby Is in an Oblique Lie

Is It Safe to Use Exercise to Induce Labor?

How Early Can You Safely Give Birth?

Read this next

What Is Back Labor and What Causes It?

Medically reviewed by Valinda Riggins Nwadike, MD, MPH

Back labor can happen when your baby's head is against your cervix.

We'll tell you what it's like and how to manage it.

We'll tell you what it's like and how to manage it.READ MORE

Can You Turn a Transverse Baby?

Medically reviewed by Valinda Riggins Nwadike, MD, MPH

As you near the end of your pregnancy, you may worry that your baby's transverse position will cause issues during delivery. Learn more about possible…

READ MORE

What You Need to Know If Your Baby Is in an Oblique Lie

Medically reviewed by Valinda Riggins Nwadike, MD, MPH

An oblique lie is a fetal position in which baby's head is just to the side of the pelvic inlet. It presents some challenges, but there are ways to…

READ MORE

Is It Safe to Use Exercise to Induce Labor?

Medically reviewed by Michael Weber, MD

If you’re pregnant and past your due date, you might wonder if exercising will help induce labor.

Here’s the truth.

Here’s the truth. READ MORE

How Early Can You Safely Give Birth?

Medically reviewed by Meredith Wallis, MS, APRN, CNM, IBCLC

Not all babies arrive on their due dates — in fact, most don't. So how many weeks early is safe to give birth? Learn more about why certain weeks are…

READ MORE

Your Guide to a Pregnancy-Safe Skin Care Routine

When you're expecting, pregnancy-safe skin care can help ensure the health of you and your baby. We'll tell you what to avoid — and some good…

READ MORE

Can Ectopic Pregnancy Be Diagnosed With Ultrasound?

Medically reviewed by Valinda Riggins Nwadike, MD, MPH

Ectopic pregnancy is a serious condition that requires accurate and swift diagnosis. Ultrasound for ectopic pregnancy diagnosis is just one tool your…

READ MORE

Is It Safe to Consume Flaxseeds During Pregnancy?

Given the inconclusive and conflicting stances about eating flaxseeds during pregnancy, it might be better to err on the side of caution.

READ MORE

Pregnancy After Miscarriage: Answers to Your Questions

Medically reviewed by Amanda Kallen, MD

Getting pregnant after a miscarriage can be an emotional experience, filled with joy but also anxiety and guilt. Learn more about pregnancy after…

READ MORE

What Is a Nurse Midwife and How to Tell If They Are Right for You

Medically reviewed by Meredith Wallis, MS, APRN, CNM, IBCLC

A nurse midwife is a nurse with education, training, and certification to provide prenatal, delivery, and women's care.

READ MORE

External Cephalic Version - StatPearls

Meaghan M. Shanahan; Caron J. Gray.

Author Information

Last Update: July 4, 2022.

Continuing Education Activity

About 25 percent of fetuses will be in breech presentation at 28 weeks, though this decreases to roughly 3 to 4 percent at term. Most infants who are in breech presentation at the time of delivery will require a cesarean delivery. However, an alternative to immediately proceeding with cesarean section is a trial of external cephalic version. This procedure successfully brings the fetus into the vertex position, the ideal position for a vaginal birth, about 58 percent of the time. External cephalic version is performed strategically placing the hands on the gravid abdomen and applying pressure to encourage the fetus to move into the vertex position. This can be attempted for fetuses in the breech, transverse, or oblique positions and has the potential to decrease cesarean delivery rates. This activity reviews the indications, contraindications, and technique involved in performing external cephalic version and highlights the role of the interprofessional team in the care of patients undergoing this procedure.

Most infants who are in breech presentation at the time of delivery will require a cesarean delivery. However, an alternative to immediately proceeding with cesarean section is a trial of external cephalic version. This procedure successfully brings the fetus into the vertex position, the ideal position for a vaginal birth, about 58 percent of the time. External cephalic version is performed strategically placing the hands on the gravid abdomen and applying pressure to encourage the fetus to move into the vertex position. This can be attempted for fetuses in the breech, transverse, or oblique positions and has the potential to decrease cesarean delivery rates. This activity reviews the indications, contraindications, and technique involved in performing external cephalic version and highlights the role of the interprofessional team in the care of patients undergoing this procedure.

Objectives:

Describe the types of breech presentation.

Outline the indications for external cephalic version.

Review the contraindications to external cephalic version.

Summarize a structured interprofessional team approach to provide effective care and appropriate surveillance of patients undergoing external cephalic version.

Access free multiple choice questions on this topic.

Introduction

About 25% of fetuses will be in breech presentation at 28 weeks, and this decreases to about 3% to 4% of term pregnancies. Most of these patients will be delivered by cesarean delivery. It is held that the overall cesarean delivery rate is higher than it should be, and efforts to prevent the first cesarean section often present obstetricians with the task of decreasing the number of cesarean deliveries they perform. One alternative to cesarean delivery is an external cephalic version (ECV). Simply, it is a procedure to change the presentation of the fetus from breech, tranverse, or oblique to vertex by applying pressure externally to the fetus through the gravid abdomen. [1]The overall success rate for the procedure is about 58% and can lead to decreased cesarean delivery rates.[2]

[1]The overall success rate for the procedure is about 58% and can lead to decreased cesarean delivery rates.[2]

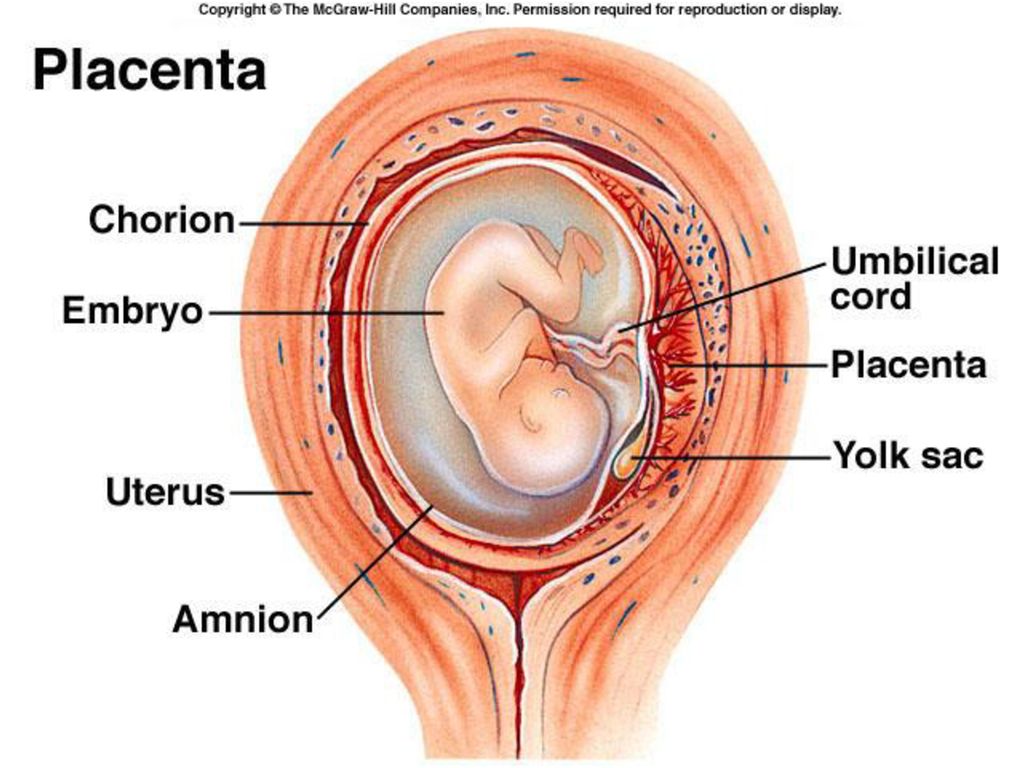

Anatomy and Physiology

ECV can be attempted with malpresentation of the fetus such as breech, transverse and oblique presentations. Complete breech occurs when the fetus has the buttocks as the presenting part and the knees are flexed with the feet near the buttocks. Frank breech occurs when the buttocks are the presenting part, and the legs are extending with the feet near the fetal head. Incomplete breech involves one bent leg and one extended leg. Transverse presentations occur when the long axis of the fetus is at a right angle to the mother with the fetal head to one side of the maternal abdomen and the back noted to be either be up or down in relation to the rest of the fetal body. Oblique presentation is when the long axis of the fetus is at a 45-degree angle to the mother, with the fetal head usually in the right or left lower quadrants.

Indications

Indications for ECV include a fetus with greater than 36 weeks of gestation with malpresentation, reassuring fetal status, and no contraindications to vaginal delivery. Most practitioners will proceed with ECV at 37 weeks to decrease the risk of preterm delivery. Factors that may increase success include multiparity, transverse or oblique presentation, complete breech, adequate amniotic fluid, and unengaged presenting part. Factors that are associated with decreased success include nulliparity, advanced dilation, estimated fetal weight of less than 2,500 grams, anterior, lateral or cornual placenta, decreased amniotic fluid or ruptured membranes, maternal obesity, frank breech, fetal spine in the posterior position, and low station with an engaged presenting part.[3]

One alternative to ECV is expectant management with possible spontaneous version, although most fetuses that will spontaneously change presentations to vertex will do so before 36 weeks gestation and are noted more often in multiparous than nulliparous women. Other alternatives are expectant management with a vaginal or cesarean delivery of the breech fetus.

Other alternatives are expectant management with a vaginal or cesarean delivery of the breech fetus.

Contraindications

Any contraindication to vaginal delivery would also be a contraindication to ECV. These include but are not limited to placenta previa, vasa previa, active genital herpes outbreak, and prior classical cesarean delivery. Prior low transverse cesarean delivery is not a contraindication to external cephalic version, although not much data is available on uterine rupture rates.[4]

Antepartum ECV is contraindicated in multiple gestations, although it can be utilized for delivery of the second twin.[5]

Consideration should be used in patients with severe oligohydramnios, nonreassuring fetal monitoring, hyperextended fetal head, significant fetal or uterine anomaly, fetal growth restriction, and maternal hypertension due to these situations being associated with a low likelihood of success of ECV and possible increased risk to the fetus from the procedure.

If a woman presents in labor with malpresentation, ECV could be a reasonable option if she is in early labor, the presenting part is unengaged, there is a normal amniotic fluid index, and no contraindications to vaginal delivery or ECV.

Equipment

Not much equipment is necessary for this procedure as it is performed with the physician's own hands. Fetal monitoring and ultrasonography are necessary components for safety and reassurance.

Personnel

An obstetrician experienced in external cephalic version is needed to perform an ECV. The procedure can be performed by one or two people. Not necessary in the room, but those that should be aware of the ECV procedure would be those needed in case of emergency cesarean delivery, such as nursing, operating room, and anesthesia staff.

Preparation

In preparation for ECV, the fetal presentation must be determined by ultrasound and fetal well-being must be assessed, usually by a nonstress test. Contraindications are reviewed with the patient to confirm that they have none. Risks, benefits, and alternatives are reviewed with the patient, and informed consent is obtained. Rh status should be known before the procedure and anti-D immune globulin administered after the procedure if indicated.

Risks, benefits, and alternatives are reviewed with the patient, and informed consent is obtained. Rh status should be known before the procedure and anti-D immune globulin administered after the procedure if indicated.

Technique

Some practitioners choose to administer a tocolytic, usually terbutaline 0.25 mg subcutaneously, 15 to 30 minutes before the procedure, if are no contraindications. Data does not support either calcium channel blockers or nitroglycerin for tocolysis in this situation.[6] Some practitioners choose to use regional anesthesia in the form of either a spinal or epidural, but data is insufficient to recommend this for all external cephalic version attempts, although it may add to success if tocolysis alone is not successful.[7]

The patient is lying supine, with a sideways tilt with a wedge to keep pressure off the aorta and vena cava. If the fetal presentation is breech, then the breech is lifted out of the pelvis with one hand, and the other hand is used to apply pressure to the back of the fetal head to attempt a forward roll. If a forward roll is unsuccessful, then a backward roll can be attempted. If the fetus is in either a transverse or oblique presentation, similar manipulation of the fetus is used to attempt to move the fetal head to the pelvis, noting a shorter distance to move than if the fetus is in a breech presentation.[8]

If a forward roll is unsuccessful, then a backward roll can be attempted. If the fetus is in either a transverse or oblique presentation, similar manipulation of the fetus is used to attempt to move the fetal head to the pelvis, noting a shorter distance to move than if the fetus is in a breech presentation.[8]

Intermittent use of ultrasonography during the procedure can be used to document fetal heartbeat and current presentation. The procedure should be abandoned if there is significant fetal bradycardia, discomfort to the patient, or if the procedure is not completed easily. Afterward, the patient should be monitored for at least 30 minutes, with fetal heart rate tracing and anti-D immune globulin given if indicated. Immediate induction is not recommended to minimize reversion, although this could be considered after 39 weeks of gestation. If ECV is unsuccessful, additional attempts can be made at the same admission or in one or more days following the initial procedure.

Complications

The most common complications associated with ECV are fetal heart rate abnormalities, occurring at a rate of 4. 7%, but these usually are transient and improve upon completion or abandonment of the procedure. More severe complications of ECV occur at a rate of less than 1% and include emergency cesarean section, premature rupture of membranes, cord prolapse, vaginal bleeding, placental abruption, fetomaternal hemorrhage, and stillbirth. Although complications are rare, ECV should be attempted in locations where an emergency cesarean section can be performed. For this reason, some practitioners chose to perform ECV in the operating room, although this is not necessary.[9]

7%, but these usually are transient and improve upon completion or abandonment of the procedure. More severe complications of ECV occur at a rate of less than 1% and include emergency cesarean section, premature rupture of membranes, cord prolapse, vaginal bleeding, placental abruption, fetomaternal hemorrhage, and stillbirth. Although complications are rare, ECV should be attempted in locations where an emergency cesarean section can be performed. For this reason, some practitioners chose to perform ECV in the operating room, although this is not necessary.[9]

Clinical Significance

Patients should be counseled on and offered ECV when appropriate. Some data show that only 20% to 30% of eligible candidates are offered ECV.[10]

Women who have a successful ECV have a lower cesarean delivery rate than women who do not, although they are still at a higher risk of cesarean delivery than women with cephalic presenting fetuses and no ECV. ECV is cost effective if the probability of a successful ECV is greater than 32%.

Enhancing Healthcare Team Outcomes

ECV is best performed by an interprofessional team. The actual procedure is performed by an experienced obstetrician aided by a labor and delivery nurse. This is not a benign procedure and it is recommended that the operating room be informed of the ECV procedure, in case of emergency cesarean delivery, such as nursing, operating room, and anesthesia staff. Fetal monitoring is necessary and steps to ensure safety must be paramount.

Review Questions

Access free multiple choice questions on this topic.

Comment on this article.

References

- 1.

Levin G, Rottenstreich A. Re: External cephalic version at term: a cohort study of 18 years' experience: External cephalic version at term: a need for modifiable predictor. BJOG. 2019 Apr;126(5):675. [PubMed: 30575279]

- 2.

Nalam RL, Chinnachamy P, Emmanuel P. External Cephalic Version: A Dying Art Worth Reviving.

J Obstet Gynaecol India. 2018 Dec;68(6):493-497. [PMC free article: PMC6207544] [PubMed: 30416278]

J Obstet Gynaecol India. 2018 Dec;68(6):493-497. [PMC free article: PMC6207544] [PubMed: 30416278]- 3.

What factors determine the success of an external cephalic version? BJOG. 2019 Mar;126(4):501. [PubMed: 30729658]

- 4.

Rosman AN, Guijt A, Vlemmix F, Rijnders M, Mol BW, Kok M. Contraindications for external cephalic version in breech position at term: a systematic review. Acta Obstet Gynecol Scand. 2013 Feb;92(2):137-42. [PubMed: 22994660]

- 5.

Bogner G, Wallner V, Fazelnia C, Strobl M, Volgger B, Fischer T, Jacobs VR. Delivery of the second twin: influence of presentation on neonatal outcome, a case controlled study. BMC Pregnancy Childbirth. 2018 May 18;18(1):176. [PMC free article: PMC5960113] [PubMed: 29776396]

- 6.

Mohamed Ismail NA, Ibrahim M, Mohd Naim N, Mahdy ZA, Jamil MA, Mohd Razi ZR. Nifedipine versus terbutaline for tocolysis in external cephalic version. Int J Gynaecol Obstet. 2008 Sep;102(3):263-6.

[PubMed: 18554601]

[PubMed: 18554601]- 7.

Carlan SJ, Dent JM, Huckaby T, Whittington EC, Shaefer D. The effect of epidural anesthesia on safety and success of external cephalic version at term. Anesth Analg. 1994 Sep;79(3):525-8. [PubMed: 8067558]

- 8.

Nagy J, Huvar I. [External cephalic version in breech presentation of fetus]. Ceska Gynekol. 2004 Nov;69(6):444-51. [PubMed: 15633412]

- 9.

Rodgers R. External cephalic version is associated with a low complication rate. BJOG. 2019 Mar;126(4):500. [PubMed: 30461156]

- 10.

Rauf B, Nisa M, Hassan L. External cephalic version for breech presentation at term. J Coll Physicians Surg Pak. 2007 Sep;17(9):550-3. [PubMed: 17903404]

Energy efficient operation of borehole pumps ETsV

Authors:

Kostyuk A.V., Candidate of Physical and Mathematical Sciences, Director of the Program of OJSC “MC “HMS”,

Tverdokhleb I.B., Candidate of Technical Sciences, R&D Director of JSC "UK" HMS "

Water supply and sanitation are industries with intensive use of pumping equipment. The share of electricity consumed by pumps is more than 50% of the total energy consumption. In this regard, the issue of reducing the cost of electricity for water supply organizations is the efficient operation of pumping equipment, incl. borehole pumps. Work in this direction is one of the priority tasks for the specialists of JSC HMS Group, the largest manufacturer of pumps in Russia for various industries. nine0003

The share of electricity consumed by pumps is more than 50% of the total energy consumption. In this regard, the issue of reducing the cost of electricity for water supply organizations is the efficient operation of pumping equipment, incl. borehole pumps. Work in this direction is one of the priority tasks for the specialists of JSC HMS Group, the largest manufacturer of pumps in Russia for various industries. nine0003

The enterprises of JSC HMS Group (JSC HMS Pumps (until June 26, 2010 JSC Livgidromash), JSC Livnynasos, JSC Plant Promburvod) produce a wide range of pumps for the water industry, and also have the ability to ensure the rapid development of individual solutions that can adapt equipment parameters to the individual requirements of the Customer's system, which significantly reduces energy consumption and increases the service life of pumping equipment.

A highly professional team of designers of the Group, with many years of experience in the field of pumping, allows you to promptly provide the Customer with the necessary advice to identify and eliminate the causes of inefficient operation of pumps. nine0003

nine0003

In addition to optimal energy consumption, the Group's pumping equipment is distinguished by reliability, confirmed by many years of experience in operating pumps at various facilities, high-quality service provision and affordable price. These factors influence the decision making when choosing a pump supplier and make the pumping equipment of HMS Group JSC competitive compared to similar equipment from Western manufacturers.

Fulfillment of the conditions for the coordinated operation of the pump in the process system

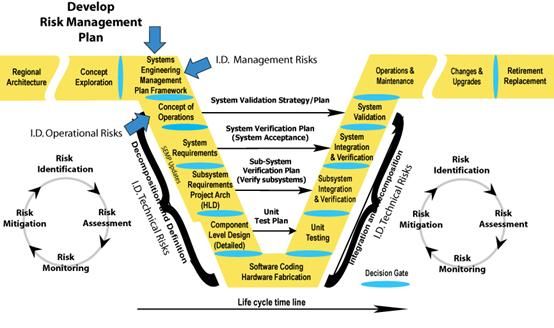

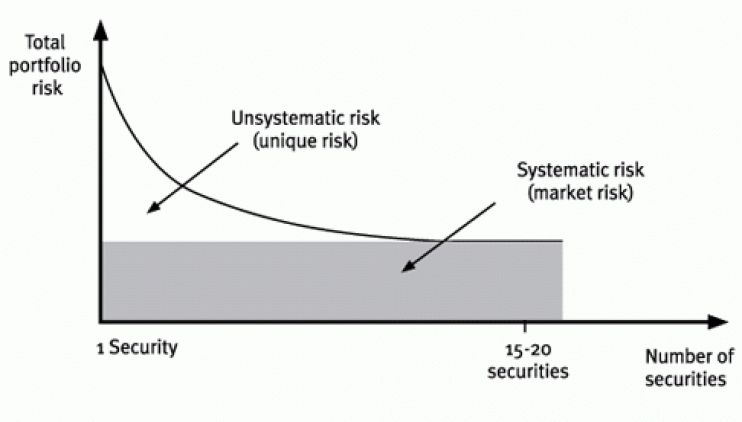

The main condition for efficient and reliable operation of pumping equipment is the coordinated operation of the pump in the system. This condition is met if the operating point, determined by the intersection of the system and pump characteristics, is within the operating range of the pump (Fig. 1):

Fig.1 Scheme of installation of the ETsV pump and characteristics of the pump and system.

In general, the characteristic of the system includes two components - static and dynamic. Thus, H sys = H stat . common . +N dyn .. The dynamic component of the system characteristic is described by a quadratic dependence on the flow - N dyn . = K*Q 2 , therefore the expression acquires the following type: H system = (H DIN . level +H Stat . . ) +K*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*QI 2 (equation 1, Fig. 1), where s - depends on losses along the length of the pipeline and losses on local resistances, N din . level – dynamic well level, N stat . syst . - static head of the system relative to the wellhead. An erroneous assessment of the required system parameters is the main reason for the incorrect selection of pumping equipment, which is explained by the difficulty of determining the dependence H din \u003d f (Q well ), losses in pipes and fittings, especially those that were in operation.

Thus, H sys = H stat . common . +N dyn .. The dynamic component of the system characteristic is described by a quadratic dependence on the flow - N dyn . = K*Q 2 , therefore the expression acquires the following type: H system = (H DIN . level +H Stat . . ) +K*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*Q*QI 2 (equation 1, Fig. 1), where s - depends on losses along the length of the pipeline and losses on local resistances, N din . level – dynamic well level, N stat . syst . - static head of the system relative to the wellhead. An erroneous assessment of the required system parameters is the main reason for the incorrect selection of pumping equipment, which is explained by the difficulty of determining the dependence H din \u003d f (Q well ), losses in pipes and fittings, especially those that were in operation.

Eliminate causes of inefficient pump operation nine0003

Among the main reasons for the inefficient operation of pumping equipment, two main ones can be distinguished:

1. Resizing of pumps, i.e. installation of pumps with flow and pressure parameters greater than required to ensure the operation of the pumping system.

2. Regulation of the pump operation mode using valves. With regard to ETsV downhole pumps, consumers quite often choose

pump with headroom, believing that this guarantees the operation of the pump under all conditions. In this case, the operating point shifts to the right zone and goes beyond the operating range, which leads to an increase in power consumption, a decrease in efficiency, an overload of the electric motor, as well as a number of mechanical problems, which significantly increases the risk of unit breakdown (Fig. 2): nine0003

Rice. 2. Characteristics of pumps with required and excess pressure.

To change the operating mode of the pump, consumers often resort to adjusting the mode using a valve installed on the pressure pipeline. This, on the one hand, allows you to obtain the required value of flow and pressure or ensure the operation of the pump within the operating range, but, on the other hand, this method of regulation leads to power losses due to throttling. nine0003

The valve power loss can be estimated from the following expression: N=ρ*g*Q 2 *(H 2 -H 1 )/1000 [kW], where N 2 , N 1 is the difference heads (pressures) before and after the valve. Often, consumers mistakenly attribute the low energy efficiency of the "pump-network" system to the low efficiency of the pump. The consequence of this is the formation of the consumer's opinion about low-quality and inefficient pumps.

When modernizing water supply facilities or replacing pumping equipment, one of the main goals is to reduce energy consumption. nine0003

nine0003

At operating facilities, it is quite easy to determine the characteristic of the system in accordance with the expression from equation 1. Knowing the value of the pressure in the system or H sys , the value of the supply Q corresponding to this value, the value of the static head, you can get the value of the coefficient k and build a characteristic. If the water consumption parameters change over time, then the characteristic must be built for the minimum, maximum and longest regime. nine0003

Methods for reducing the energy consumption of pumping units

Optimal energy consumption has a significant impact on the life cycle of a pump. The calculation of the feasibility study of competitiveness is carried out according to the life cycle cost methodology developed by specialized Western institutions.

Table #1 discusses the main methods that the US Hydraulic Institute and the European Pump Manufacturers Association report result in reduced pump energy consumption, as well as the amount of potential savings. nine0003

nine0003

Table number 1. Measures to reduce energy consumption and their potential size.

| Methods for reducing energy in pumping systems | Power consumption reduction |

| Replacing the flow control valve with | 10 - 60% nine0003 |

| frequency converter control | |

| Speed reduction | 5 - 40% |

| Cascade control with pumps installed in parallel nine0003 | 10 - 30% |

| Cutting the impeller, replacing the impeller | 10 – 20% |

| Replacement of electric motors with more efficient ones | 13% | nine0138

| Replacement of pumps with more efficient ones | 13% |

The main energy saving potential lies in the replacement of pump flow control with a valve for frequency or cascade control, i. e. application of systems capable of adapting the parameters of the pump to the requirements of the system. When deciding on the use of one or another method of regulation, it must be taken into account that each of these methods should also be applied, starting from the parameters of the system on which the pump operates. nine0003

e. application of systems capable of adapting the parameters of the pump to the requirements of the system. When deciding on the use of one or another method of regulation, it must be taken into account that each of these methods should also be applied, starting from the parameters of the system on which the pump operates. nine0003

Downhole pumps, as a rule, operate on a network with a large static component.

Fig.3. Operation of a pump with frequency regulation on a network with a predominant static component.

As can be seen from the graph (Fig. 3), when the pump is operating on a network with a predominant static component, a decrease in the pump speed leads to a decrease in the efficiency of the pump unit and a shift in the operating point to the left zone of the operating characteristic. nine0003

If at the rated speed the efficiency of the pumping unit is 60%, then a decrease to 83% of the nominal value leads to a decrease in efficiency to 35%.

Thus, when a centrifugal pump is operating on a network with a predominantly static component, the use of a frequency drive is irrational and requires a more thorough analysis and consideration of other factors.

The use of a frequency drive for downhole pumps is associated with a number of additional factors that must be considered when making a decision. nine0003

1. When the speed is reduced and the feed is reduced, the speed of the flow around the motor is reduced, which can lead to overheating. Therefore, it is necessary to know exactly how the flow will decrease with a decrease in speed if the pump works for a given system. If necessary, use cooling jackets and larger motors.

2. In the electric motors of borehole pumps, plain bearings are used, the operation of which requires the guaranteed presence of a liquid layer between the friction pairs. With a decrease in rotational speed, there is a risk of semi-dry and dry friction, which causes wear of the elements of axial and radial bearings. The reliable operation of plain bearings requires a minimum speed limit. nine0003

The reliable operation of plain bearings requires a minimum speed limit. nine0003

Fig.4. Cascade control of the operating mode of three pumps installed in parallel when working on a network with a predominantly static component. In systems with a large static component, the use of cascade control, i.e. with the connection and disconnection of the required number of pumps, on the contrary, allows you to control the operating mode of the pumps with high efficiency (Fig. 4)

Frequency control is the optimal solution when working on a system with a dynamic component. As can be seen from Fig. 5, the efficiency value practically remains constant over the entire control range. nine0003

Fig.5. The operation of the pump with frequency regulation to the network with predominant losses and friction.

findings

The studies on ECV downhole pumps presented in the article showed that the most rational way to control the pump operation mode in systems with high static pressure is cascade control, while the use of a frequency drive for ECV downhole pumps requires careful analysis and consideration of many factors.![]() nine0003

nine0003

Kostyuk A.V

Candidate of Physical and Mathematical Sciences, Director of the Program JSC "MC "GMS",

| Reviews ECV PUMP INSTALLATION Structural features of pumps ETsV This the unit is a centrifugal multistage pump rigidly, through coupling connected to a submersible asynchronous motor. pump rotors and motors are mounted in rubber-metal bearings. Cooling bearings and motor windings is carried out by pumped water (in pumps of a new generation - 2ETsV winding cooling is carried out water-glycerin mixture, which eliminates the possibility of corrosion of metal engine parts). The operating position of the pump is vertical. Working pump impeller depending on the manufacturer and specifications of the pump made of cast iron, carbon and stainless steel, polymer (reinforced and non-reinforced). Permissible water parameters - dry residue (total mineralization) - no more than 1500 mg/l; - mass fraction of solid impurities - not more than 0.01% or 100 g/m3; nine0003 - proportion of sulfates - no more than 500 mg / l; - the proportion of hydrogen sulfide - no more than 1.5 mg / l; - the proportion of chlorides - no more than 350 mg / l. Features operation of industrial borehole pumps ETsV 1. The inadmissibility of even a short-term "dry" run. This leads to bearing damage and pump failure. Since the pump is not equipped with dry-running sensors, they must be installed in the well independently and connect to the pump control station. 2. Before the pump must be filled with clean water for the first time (to ensure bearing lubrication). 3. Minimum water back-up to ensure normal operation (distance between the water surface and water intake pipe of the pump) - 1 m. 4. Powered by three-phase network 380V. 5. Working only together with control and protection stations such as "Vysota", "Kaskad", "Sugna" etc. When the pump is operated without such a station, the manufacturer's warranty for it is not distributed by! nine0003 6. Impossible pump them dirty water (that is, in which there is an excess of the proportion of solid impurities). Therefore, ETsV pumps cannot be used to pump the well. If water has increased mineralization (possibly in artesian wells) then it is necessary to purchase pumps with index G (mineralization up to 2500 mg/l) or X (up to 2200 mg/l). Installation of submersible well pumps ETsV nine0002 The pump is mounted vertically on a riser pipe (HDPE pipe) using a flange or threaded connection (depending on mating part of the pump). To the pump, in addition to the HDPE pipe, a safety stainless steel cable. Splicing pump cable and submersible cable must be done using a filler or heat shrink sleeve. To the pump, in addition to the HDPE pipe, a safety stainless steel cable. Splicing pump cable and submersible cable must be done using a filler or heat shrink sleeve. ATTENTION! Trial operation of a non-immersed pump FORBIDDEN! To protect the pump from running dry in the well, there must be dry running sensors connected to the control station are installed. The advantages of ECV engines are low compared to foreign analogues price. Currently, ETsV pumps are produced by Russia, Ukraine, Belarus and Moldova. The most reliable products of Russia ("Livnynasos", Bavlenovsky plant "Elektrodvigatel"), Belarus ("Promburvod") and Moldova ("Hydropump"). nine0003 You should be aware that the same ECV pump model of different manufacturers are structurally different. Therefore, parts from one pump may do not approach another. Regulations and installation procedure for ECV pump When installing pump takes into account the considerable depth of the well, as well as the large pump head and for drainage take pipes made of steel, interconnected threaded or flanged connections. In this case, the safety wire not used. nine0003 Installation, replacement and installation of a downhole vertical ECV pump can be done using a truck crane. Before starting the installation pump, it should be carefully and carefully inspected so that it does not have any plugs, stickers, etc. After that, the pump cable is connected to power supply cable using heat shrink sleeves. The pump is then connected with a metal drainage pipe, the second end of which is hooked with a truck crane. The height of the crane boom determines the length of the drainage pipe. Pump and pipe are lifted by a crane, after which they are placed in the wellhead with an installed a device for fixing a column of pipes for draining water. Next control of the ETsV pump is carried out thanks to the Control and Protection Station, which protects the equipment in case of electricity overload, if the pump will turn off due to a phase failure, after an emergency shutdown, and so on. Launch pump ETsV After After the pump is installed inside the well, commissioning begins. Electric motor after immersion, filled with water and first switched on of this apparatus is carried out when the valve is open. When systems are starting up, it is important to correctly determine the direction of rotation. After the device is turned on, they look for a while to see what the feed will be. and water pressure. After that, they turn it off, change the location of any two phases and turn on again, monitor the pressure and water quality. If the direction is chosen correctly, then the pressure will be strong. Next, the pump is discharged into operating mode, and the water pressure is regulated using a special valve. If in water supplied by the pump, mechanical impurities appeared, then the degree of supply reduce. If this does not help, then the device is turned off and the cause is looked for. the appearance of impurities, eliminate it and turn on the unit again. nine0003 Pump must be selected taking into account the fact that the flow rate of the well should be at least a quarter more than the nominal supply of the apparatus. Dismantling and pump replacement Replacement and dismantling of the pump can be carried out for a variety of reasons: 1. As a rule, the pump worked quite long without failure, but its performance began to file over time and get worse. Gradually, he stops pumping water altogether. If this happened, then the device needs to ring and if the motor winding produces a short short circuit or open circuit, then the pump is taken out of the well, it turns out and the cause of the breakdown is removed. 2. Silting or sanding in well. In this case, the pump must be dismantled and cleaned, as well as cleaned the well itself. nine0003 3. Due to wear of the impellers the water supply part of the pump may not function. 4. If the pump is not equipped with a special protection, the device may break due to a voltage drop. Relay and output accumulators fail, and the pump often turns off and on. AT As a result, the electric motor breaks down quickly. 5. If the pump was selected and installed with from the very beginning is wrong with respect to the parameters of the well, then he quickly falls into disrepair. The dynamic moisture level should always be above the pump, where its suction cavity is located. nine0003 6. If during operation allowed errors, the pump will also need to be dismantled to repair or identify faults. When replacement or dismantling is carried out, the pump is lowered into the well in a tube made of metal or plastic. Safety wires can also be used or special equipment in the form of cranes. The pump is centered inside the well, after which it fix. For correct and effective replacement of the pump in the well, you need to choose the right device, put it at the calculated depth, and also choose the most suitable pipes for lifting water, install a system if necessary insurance. After dismantling the pump, it is worth conducting video diagnostics of the well, since such way it is possible to objectively assess its degree of deterioration and performance. The operating periods for wells are determined in different ways. If all the necessary conditions for the installation and use of the pump are met, then problems are unlikely. REQUIREMENTS FOR THE INSTALLATION OF PUMPS IN THE WELL In case the required pump capacity is higher well debit, it is necessary to install a dry running sensor. Then the pump will work intermittently. It must be remembered that the number of starts and the interval between them must correspond to the values \u200b\u200bspecified in the manual for pump operation. Possible defects during installation of the casing string (pipe misalignment at the welding point, poor weld quality, curvature of the casing) can make it difficult or impossible to install pump. During installation work, it is recommended to check the well to the installation depth of the pump with a caliber of the corresponding diameter. For stable operation of the pump, it is necessary that the pressure the pump branch pipe was below the dynamic level of the well by at least 1 meter. The installation level must be measured from the pump inlet. Installation level pump on the lower end of the motor must be at least 1 m above the well filter, to protect against sand entering the pump and increased wear of its elements. The diameter of the pressure pipe must be equal to the size pump discharge port, or differ slightly from it. Decrease the diameter of the lifting column leads to an increase in friction losses, and its a significant increase in the cost of the pipeline. Therefore, when choosing the diameter of the pressure pipeline must be based on the condition: flow velocity liquid must be within 1.5 - 3.0 m/s ERRORS IN THE SELECTION AND OPERATION OF WELL PUMPS Most of the problems associated with frequent exits from failure and excessive power consumption of pumping equipment, are laid on the stage of its selection, as well as its maintenance by unqualified personnel. 1. Installation and operation of a pump with excessive parameters (flow and pressure) relative to those required, i.e. "oversized" pump, leads to unreasonably high costs for the purchase of equipment (at the stage of construction of the facility, when changing the characteristics of the system). For this case is characterized by the following: - a significant excess of the value consumed current relative to the nominal; - frequent crashes control and protection station (CPS) provided that it complies with pump parameters; — frequent switching on/off of the pump. Pump operation in this mode can lead to the following points: - an increase in turbidity and volume sand in the pumped water, clogging of the well filter, deterioration of the quality water; - an increase in the energy consumed by the pump with a decrease in efficiency; - overheating electric motor; - breakdowns of the insulation of the stator windings; - "surfacing" of workers wheels and their wear due to friction against the stationary parts of the pump. 2. Running the pump at low flow results in to the following: - insufficient cooling and overheating of the electric motor, melting of the stator windings; - increased bearing wear due to insufficient lubrication; — decrease in pump efficiency. 3. Selection of equipment according to the maximum values of pressure and filing. It must be remembered that in addition to working with maximum load there are other operating modes of the pump. Therefore, if possible, use storage tanks and apply various methods regulation. nine0003 4. Operation of the pump without a cooling jacket in the well large diameter Installation of a pump with a significantly smaller diameter well leads to a significant decrease in the rate of cooling liquid flow electric motor and, as a result, to overheating and decrease engine resource. The pump diameter must be selected so that the fluid flow rate was at least 0. Thus, the pump diameter is selected according to from the required value of the pump delivery (Fig. 9): where: D - well diameter, m d - pump diameter, m Q - pump delivery, m3/h v - average fluid velocity, m/s. Next, the pump with the closest diameter is selected from the catalog. In case when it is impossible to ensure a fluid flow rate of at least 0.2 m/s, it is necessary use a special cooling jacket for the pump motor. 5. Selection of smaller diameter lifting pipes The use of lifting pipes with a diameter smaller than the diameter of the pressure pipe threaded connection or flange, as a rule - in order to save money, leads to large friction losses and an increase in the required head. It is possible that at the consumer will not be able to receive the required flow. nine0003 6. Small cable selection Connection pump motor to the mains using a cable with a smaller cross section recommended leads to overheating of the cable and a significant drop voltage, which adversely affects the operation of the electric motor. 7. Poor quality of supply voltage and lack of control and protection stations Connecting the pump directly to the mains is not allows you to protect the electric motor from the most typical causes of failure system: skew and phase failure, significant voltage deviations from the nominal values, etc. nine0003 8. Removing the built-in non-return valve is significantly increases the risk of mechanical damage to the pump due to water hammer. Except In addition, with a non-return valve in the event of a power failure the pump is untwisted in the opposite direction by the flow of fluid from lifting pipe. Starting the pump at the moment of such reverse rotation can cause damage to the motor. 9. Exceeding the pump flow rate of the well, specified in the passport, can lead to operation in the "dry running" mode, which causes: - overheating electric motor; - rapid wear of bearing assemblies; - increased corrosion. 10. Absence of instrumentation Availability instruments for measuring the water level in the well, pressure, water flow, voltage and current strength, the number of starts and the operating time of the pump allows receive data on the operation of pumping equipment and system characteristics. This allows you to identify deviations in the operation of the pump due to changes in conditions operation and performance of the water supply system, and ensure efficient operation of pumping equipment. nine0003 Connection diagram

CABLE SIZING AND CONNECTING THE BOREHOLE PUMP The choice of cable section is made based on the conditions permissible current load, maximum ambient temperature and the maximum allowable voltage drop of 2% of the nominal values. To select the cross section of a conductive cable, see table on page 87. Please note: since different brands of aggregates of the same power of the engine used in them can consume different current, the choice of length and cross-section of the cable should be carried out according to rated current to avoid cable oversizing. SELECTION OF PUMP CONTROL STATIONS The selection of the control station is made in accordance with rated current consumption of the motor of the pumping unit. Technical engine characteristics are given in the corresponding section of the catalog, also they can be specified in the passport of the pumping unit, on the nameplate engine or by contacting the manufacturer of the unit. For example, for an ETsV pump 6-10-110 the rated current of the electric motor is 12 A, therefore, for for this pump, you must select the control station HMS Control L3-25-… (full designation - in accordance with the designation structure). If failed to select a station on their own, or presented in the catalog modifications do not meet all requirements, it is possible to complete and send to CJSC "HYDROMASHSERVICE" (United Trading Company of the Group HMS) questionnaire (see page 88). For pumps from 7.5 kW it is recommended to use control stations that provide soft start engine. |

nine0017

nine0017  nine0003

nine0003

After the pump placed in the well, the upper part of the pipe is attached to the wellhead and moored with a truck crane, which then lifts a second pipe, which leads to the well and connects to the first. The first pipe is removed from fixation and two pipes are placed inside the well. After the upper part of the second pipe is attached to the wellhead and another pipe is brought to it, and so on. The pump is lowered to until it reaches the required depth. While the pump is lowering, using plastic clamps, the cable is attached to the drainage pipes. nine0003

After the pump placed in the well, the upper part of the pipe is attached to the wellhead and moored with a truck crane, which then lifts a second pipe, which leads to the well and connects to the first. The first pipe is removed from fixation and two pipes are placed inside the well. After the upper part of the second pipe is attached to the wellhead and another pipe is brought to it, and so on. The pump is lowered to until it reaches the required depth. While the pump is lowering, using plastic clamps, the cable is attached to the drainage pipes. nine0003  At system terminals voltage must be at least 360 V.

At system terminals voltage must be at least 360 V.  However, the maximum depth for The pump must not be larger than the nominal head of the water. For that, so that the electric motor is properly cooled, the lower part of the apparatus is placed higher well filter zones per meter.

However, the maximum depth for The pump must not be larger than the nominal head of the water. For that, so that the electric motor is properly cooled, the lower part of the apparatus is placed higher well filter zones per meter.

nine0003

nine0003  During installation pump must be guided by the requirements of the passport attached to it and operating instructions

During installation pump must be guided by the requirements of the passport attached to it and operating instructions  The most typical errors are listed below.

The most typical errors are listed below.  Feed control an “oversized” pump with a valve leads to unnecessary losses friction power. nine0003

Feed control an “oversized” pump with a valve leads to unnecessary losses friction power. nine0003  2 m/s.

2 m/s.

In case the worker motor current is 10% lower than the rated current, 10% longer cable can be used, than indicated in the table. For example, you need to choose a cable for the pump ETsV 8-25-125 power 13 kW with a rated current of 33 A. The required length is 160 m. table on page 87 with a power of 13 kW and a current of up to 35 A (vertical column) in the corresponding row we find the cable length of 175 m, which corresponds to the cross section of the conductive core 25 mm2. Thus, with a length cable 160 m for this pump, you must select a cable with a cross section of 25 mm2. The correct connection of the power supply of the pump motor is determined by direction of rotation of the pump. When the valve is closed, the pressure gauge will show two different pressures. The larger one points in the right direction rotation of the electric pump. For a downhole electric pump, the rise of water at normal operation should be noted 1-2 minutes after start-up. At incorrect direction of rotation of the rotor, the connection of any two phase motor power wires.

In case the worker motor current is 10% lower than the rated current, 10% longer cable can be used, than indicated in the table. For example, you need to choose a cable for the pump ETsV 8-25-125 power 13 kW with a rated current of 33 A. The required length is 160 m. table on page 87 with a power of 13 kW and a current of up to 35 A (vertical column) in the corresponding row we find the cable length of 175 m, which corresponds to the cross section of the conductive core 25 mm2. Thus, with a length cable 160 m for this pump, you must select a cable with a cross section of 25 mm2. The correct connection of the power supply of the pump motor is determined by direction of rotation of the pump. When the valve is closed, the pressure gauge will show two different pressures. The larger one points in the right direction rotation of the electric pump. For a downhole electric pump, the rise of water at normal operation should be noted 1-2 minutes after start-up. At incorrect direction of rotation of the rotor, the connection of any two phase motor power wires. nine0003

nine0003