How to do a membrane sweep yourself

Stretch and sweep | Pregnancy Birth and Baby

Stretch and sweep | Pregnancy Birth and Baby beginning of content3-minute read

Listen

What is a stretch and sweep?

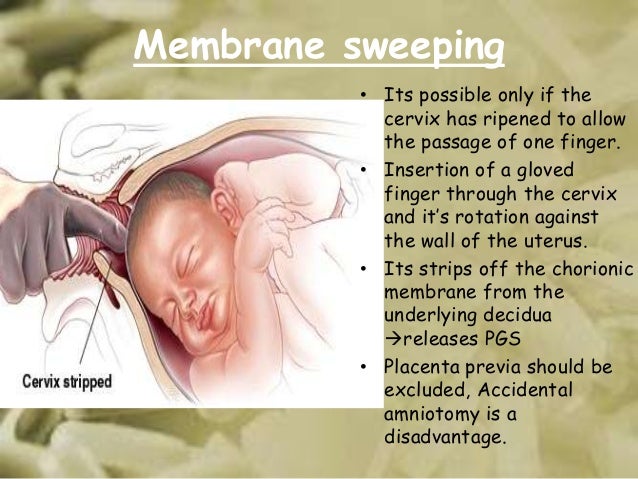

A stretch and sweep or membrane sweep is a relatively gentle way of trying to start labour. It is a simple procedure that sometimes initiates labour, reducing the risk of babies being born over the due date (42 weeks of pregnancy).

When is a stretch and sweep offered?

Your midwife or doctor may offer to perform a stretch and sweep when you have reached full term (38 weeks) to try to start labour. Some hospitals and doctors recommend the procedure only if you are 40 to 41 weeks pregnant in an attempt to prevent an overdue delivery, which may place the baby at risk.

What to expect from a stretch and sweep

The procedure is carried out by a midwife or doctor as part of an internal vaginal examination. They put a couple of lubricated, gloved fingers into your vagina and insert their index finger into the opening of the cervix or neck of your womb

They then use a circular movement to try to separate the membranes of the amniotic sac, containing the baby, from your cervix. This action, which releases hormones called prostaglandins, prepares the cervix for birth and may initiate labour.

Your midwife or doctor will:

- check the estimated date of delivery

- ask you to empty your bladder and lie down

- detect your baby’s position by feeling your abdomen

- do an internal examination to find if your cervix is closed or open

- massage around the neck of your womb if it is soft but closed — this 'stretch' can stimulate your body to release prostaglandins, which encourage the cervix to open

- insert an index finger into the neck of the womb, if it is open, and use circular motions to loosen or 'sweep' the amniotic sac membranes from the top of the cervix — this triggers the release of hormones and may start labour

If you find the procedure too uncomfortable, ask your midwife or doctor to stop.

Afterwards you might experience:

- discomfort

- mild or occasionally strong pain

- slight bleeding

- cramps or irregular contractions

Take paracetamol and have a warm bath if you are in pain. If your membranes rupture, the pain is bad or you have fresh, red bleeding, contact your midwife, doctor or maternity unit.

The process can be repeated if labour does not start over the next couple of days.

What are the benefits and risks of a stretch and sweep?

Stretch and sweep procedures at 41 weeks of pregnancy greatly reduce the percentage of women who deliver their babies beyond term. They may be offered as an alternative to inducing birth through medication or by rupturing the membranes.

The procedure is safe in a normal pregnancy. There is a slight chance the membranes may break during the procedure.

Ask your doctor or midwife about the benefits and risks before agreeing to a stretch and sweep procedure.

Sources:

BabyCenter (What is a membrane sweep?), Queensland Health (Queensland Clinical Guidelines, Induction of labour), The Royal Hospital for Women (Sweeping membranes to encourage spontaneous labour), Cochrane (Membrane sweeping for induction of labour), NSW Health (Pregnancy beyond 41 weeks)Learn more here about the development and quality assurance of healthdirect content.

Last reviewed: January 2021

Back To Top

Related pages

- Having the baby

Need more information?

Disclaimer

Pregnancy, Birth and Baby is not responsible for the content and advertising on the external website you are now entering.

OKNeed further advice or guidance from our maternal child health nurses?

1800 882 436

Video call

- Contact us

- About us

- A-Z topics

- Symptom Checker

- Service Finder

- Linking to us

- Information partners

- Terms of use

- Privacy

Pregnancy, Birth and Baby is funded by the Australian Government and operated by Healthdirect Australia.

Pregnancy, Birth and Baby is provided on behalf of the Department of Health

Pregnancy, Birth and Baby’s information and advice are developed and managed within a rigorous clinical governance framework. This website is certified by the Health On The Net (HON) foundation, the standard for trustworthy health information.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This information is for your general information and use only and is not intended to be used as medical advice and should not be used to diagnose, treat, cure or prevent any medical condition, nor should it be used for therapeutic purposes.

The information is not a substitute for independent professional advice and should not be used as an alternative to professional health care. If you have a particular medical problem, please consult a healthcare professional.

Except as permitted under the Copyright Act 1968, this publication or any part of it may not be reproduced, altered, adapted, stored and/or distributed in any form or by any means without the prior written permission of Healthdirect Australia.

Support this browser is being discontinued for Pregnancy, Birth and Baby

Support for this browser is being discontinued for this site

- Internet Explorer 11 and lower

We currently support Microsoft Edge, Chrome, Firefox and Safari. For more information, please visit the links below:

- Chrome by Google

- Firefox by Mozilla

- Microsoft Edge

- Safari by Apple

You are welcome to continue browsing this site with this browser. Some features, tools or interaction may not work correctly.

Purpose, Procedure, and What Happens After

I was pregnant with my son during one of the hottest summers on record. By the time the end of my third trimester rolled around, I was so swollen I could barely turn over in bed.

At the time, I worked in our local labor and delivery unit as a nurse, so I knew my doctor well. At one of my checkups, I begged her to do something to help spur my labor.

If only they would strip my membranes to induce labor, I reasoned, I could be out of my misery and meet my baby boy sooner.

Here’s a look at how effective membrane stripping is for inducing labor, plus the risks and benefits.

Stripping the membranes is a way to induce labor. It involves your doctor sweeping their (gloved) finger between the thin membranes of the amniotic sac in your uterus. It’s also known as a membrane sweep.

This motion helps separate the sac. It stimulates prostaglandins, compounds that act like hormones and can control certain processes in the body. One of these processes is — you guessed it — labor.

In some cases, your doctor can also gently stretch or massage the cervix to help it start to soften and dilate.

Your doctor may suggest trying a membrane stripping if:

- you’re near or past your due date

- there isn’t a pressing medical reason to induce labor with a faster method

You don’t need to do anything to prepare for a membrane stripping. The procedure can be done in your doctor’s office.

The procedure can be done in your doctor’s office.

You’ll simply hop up on the exam table like at a normal checkup. The best thing you can do during the procedure is simply breathe through it and try to relax. Membrane stripping doesn’t take long. The entire procedure will be over in a few minutes.

Researchers on a study published in the Journal of Clinical Gynecology and Obstetrics (JCGO) didn’t find any increased risks for negative side effects in women undergoing membrane stripping.

Women who have their membrane swept aren’t more likely to have a cesarean delivery (commonly referred to as a C-section) or other complications.

The study concluded that membrane stripping is safe and that, in most cases, women will only need to have the procedure one time for it to work.

Experts still question whether or not membrane stripping is really effective. A 2011 review of available studies concluded that the efficacy depends on how far along in pregnancy a woman is, and whether or not she uses other induction methods. It’s most effective if she doesn’t.

It’s most effective if she doesn’t.

The JCGO study reported that after a membrane sweep, 90 percent of women delivered by 41 weeks compared to women who didn’t receive the membrane sweep. Of these, only 75 percent delivered by 41 weeks’ gestation. The goal is to stimulate labor and safely deliver before the pregnancy is beyond 41 weeks, and membrane stripping may occur as early as 39 weeks.

Membrane stripping might be most effective for women who are past their due dates. One study found that membrane sweeping could increase the likelihood of spontaneous labor within 48 hours.

Membrane stripping isn’t as effective as other types of induction, such as using medications. It’s generally only used in situations when there really isn’t a pressing medical reason to induce.

Advice from a nurse educator This procedure does cause some discomfort and should only be done by an experienced doctor. You may experience bleeding and cramping for a few days following the procedure. But if it works, it could save you from having your labor induced with medication.

But if it works, it could save you from having your labor induced with medication.

Advice from a Nurse Educator

This procedure does cause some discomfort and should only be done by an experienced doctor. You may experience bleeding and cramping for a few days following the procedure. But if it works, it could save you from having your labor induced with medication.

The bottom line is you’ll need to balance your discomfort with other adverse effects.

— Debra Sullivan, PhD, MSN, RN, CNE, COI

To be honest, a membrane stripping isn’t a comfy experience. It can be uncomfortable to go through, and you may feel a bit sore afterward.

Your cervix is highly vascular, meaning it has a lot of blood vessels. You may also experience some light bleeding during and after the procedure, which is completely normal. However, if you’re experiencing a lot of bleeding or in a lot of pain, be sure to go to the hospital.

Membrane stripping is most effective if a woman:

- is over 40 weeks in their pregnancy

- doesn’t use any other type of labor-inducing techniques

In those cases, the JCGO study found that women on average went into labor on their own about a week earlier than women who didn’t have their membranes swept.

If you’re reaching a stage in your pregnancy where you’re feeling miserable, talk to your doctor about the pros and cons of a membrane induction. Remember that unless there’s a medical concern, it’s usually best to let your pregnancy progress naturally.

But if you’re past your due date and you don’t have a high-risk pregnancy, a membrane stripping might be a very effective and safe way to help put you into labor naturally. And hey, it might be worth a shot, right?

Do-it-yourself vibrating table for paving slabs, drawing of a vibrating table for paving slabs

Vibrating table is used to increase the density and uniform distribution of the concrete mixture in the form. Such equipment is not cheap. But for home production of tiles or concrete blocks, it makes no sense to buy complex and expensive structures.

Scheme of a vibrating table for the manufacture of paving slabs and blocks

0003

How to make a vibrating table for paving slabs with your own hands?

The size of the equipment depends on the shape of the products and the amount of work. The optimal dimensions of the countertop for self-production of small batches of paving slabs are 700x700 mm. When making a vibrating table for blocks with your own hands, increase the length of the tabletop to 2000 mm.

The optimal dimensions of the countertop for self-production of small batches of paving slabs are 700x700 mm. When making a vibrating table for blocks with your own hands, increase the length of the tabletop to 2000 mm.

Here you can find the catalog of vibrating tables for paving slabs, sold by TechMash Group LLC. nine0019

Required materials are shown in the table

Attention: all dimensions indicated in the article are for reference only and may vary depending on the power of the vibrator and table dimensions.

| Vibrating table support | |||

| Frame | Feet | nine0041 ||

| Materials | Section dimensions | Materials | Section dimensions |

| Metal angle, channel or pipes of any profile. | Corner shelf min. 30 mm | nine0083 Ø round pipes 1.5–2" | |

| Ø round pipes from 1" | Square section 44x44 mm | ||

| Square from 25x25 mm | |||

| nine0002 Bolts for mounting shock absorbers (for better fixation, a rubber hose is put on the bolts). | M14x40 | Soles 1.5 mm thick | sheet 55x55x1.5 mm |

| Crossbar Angle | 20 x 20 x 1.5 mm | ||

| Worktop | |||

| Materials | Dimensions | ||

| Sheet metal | Thickness 8-10 mm | ||

| Frame tube | Section 40x20 mm or 40x40 mm | ||

| Channel for engine mounting | No. | ||

| Nuts for fixing shock absorbers | М12 | ||

| Thick rim rod |

| ||

| Shock absorbers | |||

| Steel springs (6 pieces) | |||

| In some cases, rubber shock absorbers are used to ensure the minimum amplitude of vibration. nine0003 | |||

| Vibrator | |||

| 220 V unbalance motor | |||

How to work

For work you will need:

• a welding machine with a power that allows you to weld metal with a thickness of 4 mm;

• electrodes Ø 3 mm (for semi-automatic machines - welding wire Ø 0.8)

• grinder;

• drill;

• bolts and nuts; nine0263 • tape measure.

Assembly of the base

Work begins with the welding of the frame. It is made of a metal channel or corner. To make the structure sufficiently rigid and durable, use corners with a thickness of 1.5 mm and a shelf size of 30 mm or more.

Four legs are welded to the frame, made of a pipe of any profile (square section dimensions - 44x44x1.5 mm; round section diameter - 2", thickness - 1.5 mm). worker preferences.For a person of average height (175 cm), the recommended table top height is 90 mm.

If necessary, the table height can be reduced to 60 mm. This makes it easier to pour concrete and remove molds. But make sure that the engine does not touch the floor.

The legs must be the same size, otherwise the table top will tilt and the mortar will run out when it vibrates.

To increase the strength between the legs, it is desirable to weld crossbars or spacers. For them, a corner with dimensions of 20x20x1.5 mm is enough.

Important: for the stability of the vibrating table under the legs, it is necessary to weld "soles" - steel plates measuring 55x55x1.5 mm, which are bolted to the floor. If you do not plan to move the vibrating table, then concrete the legs. nine0003

At the corners of the frame, pins or bolts M14x40 are welded, intended for mounting shock absorbers. A rubber hose is put on them, fixing and sealing the connection.

A steel sheet is welded on the side for mounting the socket and switch.

Worktop assembly

It is preferable to use 8-10 mm thick steel sheet for the work surface. On the reverse side of the tabletop, a frame is welded, made of a square profile pipe with a section size of 40x40 mm. Nuts for fastening shock absorbers are welded to the frame. nine0003

The table cover must have sides that prevent the forms from slipping during the operation of the vibrating table.

A channel is welded to the middle of the countertop on the reverse side, to which a vibrator is attached.

The table top must be smooth. Hollows and bulges reduce the quality of the surface of the tile. To ensure that the concrete is evenly distributed over the forms, carefully set the level when installing the countertop.

Shock absorbers

Shock absorbers transmit vibrations that occur during engine operation to the tabletop. Steel springs are used as shock absorbers. Well suited springs from a moped, cut into two parts, from valves or shock absorbers of an automobile engine. Shock absorbers are located in each corner of the tabletop and in the center of the long sides.

Bolts or metal pins are welded onto the bed frame. For a reliable connection, a rubber hose is put on them - at the height of the bolts, the shock absorbers are rigid, only the upper part of the connection springs. nine0003

The height of the fastener is 1/3 of the length of the springs. Shock absorbers are welded to the tabletop. Metal cups can be used instead of bolts. In this case, the springs are inserted inside.

In this case, the springs are inserted inside.

A completely permanent connection is also possible: the shock absorbers are welded at one end to the frame, and at the other end to the working surface.

Vibrator

The unbalance motor is rigidly fixed to the worktop. To do this, a channel is welded to the reverse side of the working surface, four holes are made for the bolts. The vibrator is fastened with bolts through washers and engravers. nine0003

We recommend using IV-98 and IV-99 platform vibrators. These are popular models that are always on sale. If necessary, the motor can be easily replaced. For home use, a 220 V model is suitable. Otherwise, it is necessary to weight the structure with concrete ballasts.

As a vibrator, you can also use household electric motors (for example, from a washing machine) with a homemade eccentric. They have less power, but can withstand only 20-30 start-up cycles. nine0003

Vibrator adjustment

Disturbing force in kN is calculated by the formula:

F = 30(Ms + 0. 3Mb) / 1000

3Mb) / 1000

where, Ms is the weight of the countertop;

Mb is the mass of concrete.

To reduce the vibration amplitude, change the weight or size of the unbalance plates.

Other

Paint the structure with 3 in 1 Rust Primer for corrosion protection. The coating is applied in three layers. The paint dries quickly, does not require preliminary cleaning of the surface from rust, and is resistant to water and oils. nine0003

Category in the catalog:

Vibrating tables for paving slabs

Share:

How to solder a PVC membrane with a hairdryer and how to glue it

In this article we will see how to solder a PVC membrane with a hairdryer, what kind of material is it and why is it in demand now only grows.

In this article, we will see how to solder a PVC membrane with a hairdryer, what kind of material it is and why the demand for it is only growing now. We will find out how to glue the PVC roofing membrane and at what stage of laying the cake it should and can be used. Consider the positive and negative aspects of using the material, and appreciate the possibility of laying the film with your own hands. nine0003

Consider the positive and negative aspects of using the material, and appreciate the possibility of laying the film with your own hands. nine0003

How to glue the roofing membrane?

Now it has become a trend to install a built-up membrane roof, let's see what it is and how to glue it. PVC membrane is an innovative material, the use of which is only gaining momentum, but we are sure that it will become very popular. This is due to the fact that the material has high performance characteristics, it has practically no equal in waterproofing properties.

The membrane began its history forty years ago, for the first time it began to be widely used in European countries. And already now, 80% of the building stock in the EU uses PVC sheeting in the roofing device. The basis of the material is polyvinyl chloride, but there is more than one layer in it, each of them improves the quality characteristics of the product: nine0003

- PVC layer;

- reinforced mesh;

- dark color bottom layer.

The first is made of PVC, which provides hygroscopicity, high stability when exposed to sunlight or temperature changes. The second layer performs the function of a “frame”, but the last, darker layer helps to identify roof defects that may appear both during installation and during operation. If there are gaps and dents on the work surface, the difference in the intensity of the color of the layers will help to identify them. But the sooner you notice and fix it, the cheaper it will cost. nine0003

PVC can be used on all types of roofs, the material is especially popular for the installation of turnkey membrane roofing, both in operation and not. Of the advantages, one can say about the low weight of the canvas, so its installation will not create an additional high load on the roof and the structure as a whole. Rolls can be found in various lengths and widths, which allows you to choose the right size. Installation of PVC membranes is quite simple and even minimal skills are enough.

How to install the PVC membrane correctly? nine0005

Each material has its own laying technique, and often, when mentioning PVC membranes, the question arises of how to lay it correctly. We have already said that even a non-professional can do this. The material can be used inside the roofing pie, and even in the external arrangement of the roof. This is due to the high rates of resistance to adverse weather factors. And the canvas itself is very durable, but at the same time, and elastic.

The PVC surface is vapor-permeable, which allows condensate to be removed from the roofing pie. In addition, the canvas can be laid even on an imperfectly flat surface. Another plus is resistance to open fire, which not all materials can boast of, for example, oil products such as bitumen ignite very quickly. nine0003

PVC membrane is able to withstand contact with acids and alkalis, but cannot get along with bitumen and polystyrene at all. It is also not worth using solvents in conjunction with PVC sheeting. For laying sheets, it is better to use heated air, and laying should be done not in a joint, but with an overlap, which will create a strong seam, and the surface will be more integral, which will increase the waterproofing properties.

For laying sheets, it is better to use heated air, and laying should be done not in a joint, but with an overlap, which will create a strong seam, and the surface will be more integral, which will increase the waterproofing properties.

DIY PVC membrane

How to lay a PVC membrane with your own hands, in order to save on the work of professionals. Before starting work, you need to determine all the factors that may affect the result. The first is the distance between the rafters, which should not be more than 1 meter. If you decide to lay the membrane inside the roofing pie, then the distance between the insulation and waterproofing should not be less than four centimeters. nine0003

The laying direction is also important to observe - from the eaves to the ridge, and it is not worth stretching the canvas to the limit, it is even better to leave a little sagging, but not more than 2 centimeters. As we have already said, for a long service life of the roof, it is better to overlap such materials, just as when laying a soft roof of a rolled (/services/rulonnaya-krovlya/) roof, but the size of the overlap depends on the angle of the roof.

In order to lay your own, you will need some tools and solutions. For example, adhesive, self-tapping screws, scissors, it is better to choose large and durable ones, a screwdriver, a jack thread, wax chalk, and most importantly, welding equipment. Before starting work, however, as always, a thorough cleaning of the surface from debris is required, and it is also necessary to dismantle all antennas, stairs, signs, etc. Sometimes it is required to dismantle the old coating. nine0003

How to glue membrane roofing?

After the preparatory work has been carried out, you can begin to think about how to glue the membrane roof. Before laying, it is necessary to lay out a drainage layer, for this it is better to use needle-punched geotextiles and how it differs from bonded, we have already told. For better heat retention, you can lay a layer of basalt wool or expanded polystyrene. Only after that you can start installing the PVC membrane. To do this, you need to carefully lay out the material on the work surface and fix it with special fasteners.

Thickness 1.5 mm. The length depends on the dimensions of the structure.

Thickness 1.5 mm. The length depends on the dimensions of the structure.  8 (80x40 mm)

8 (80x40 mm)