How to open a child proof bottle

How To Open Child Proof Cap With Tricks

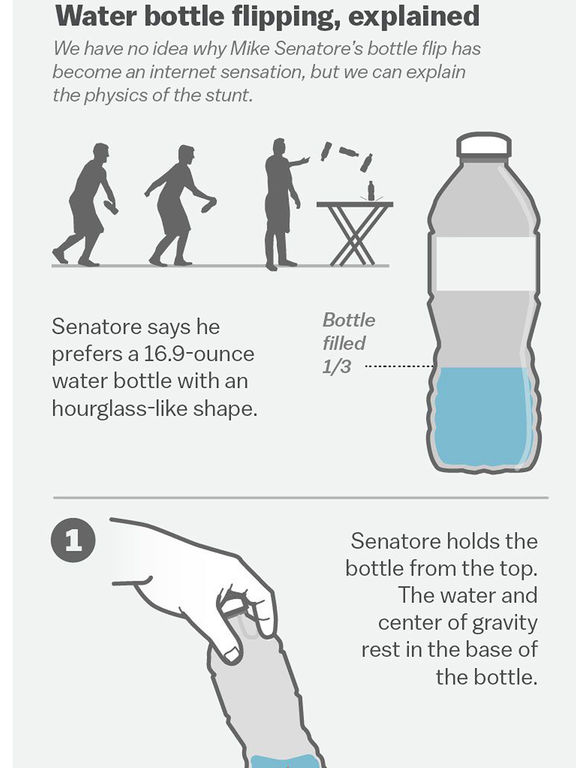

Most prescription drugs are packaged in childproof containers, which require a certain amount of manual skill and arm strength to get them opened. Childproof caps are specifically designed to prevent children from accidental poisoning. But at times, you may also find it challenging to open childproof pill containers if you suffer a temporary loss of strength due to injury or arthritis. Certain situations require you to adopt techniques of bottle opening to your advantage. Keep reading to learn how to open childproof caps.

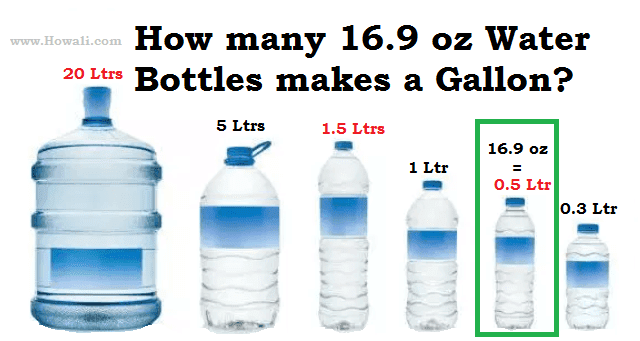

How Does a Childproof Cap Work?Child-resistant packaging, with a distinct safety cap or childproof cap, is a unique packaging used to reduce the risk of children ingesting hazardous materials. This child-resistant packaging can be a problem for some adults or people with disabilities. There are many different childproof caps designs available. The most common is one that you must push down and turn at the same time.

The cap is made of two caps, one inside the other, the cap has threads that screw into the container, and the outside cap has the grippy edges that allow you to twist it easily. The two caps can turn one inside the other. If you push down hard, the grippy flat surfaces between the two caps will mesh or connect and allow you to unscrew the inside cap from the bottle, by spinning it through the outside lid. The childproof cap is a notable invention that paved the way for medicine safety and accident prevention for decades. Not every adult is an expert at doing the skillful opening, and it is a necessity to have an idea on how to open childproof caps.

Ways to Open Childproof CapsThere are many ways to open a childproof cap. You can do it by opening the container properly as directed, using the edge of a table, using a flat surface, or using a bottle opener. Keep reading to know which technique on how to open childproof caps, will work best for you.

You can do it by opening the container properly as directed, using the edge of a table, using a flat surface, or using a bottle opener. Keep reading to know which technique on how to open childproof caps, will work best for you.

With this method, you need to place the container on a flat surface for a good grip on the container. Check the label first to know what type of childproofing is on the bottle. Childproof containers have their particular locking mechanism, and it’s essential to use the right motions to open it. Some would have the “push and turn down” instruction where the lid has an arrow that points down. With this, you need to squeeze the sides and turn, push down the tab and turn, and try opening the container.

Using the Edge of a TableIf you opt for this method, you need to find a table with a wide edge to provide you with enough leverage to rotate the cap. First, hold the container, so the bottom part of the cap or lid rests against the table’s top edge. The top and the bottom part of the cap must be placed between the edge of the table. Next, pull the container in a quick, downward motion against the side of the table. The cap will click and release as you move it down against the edge. It is an effective way of how to open childproof caps.

The top and the bottom part of the cap must be placed between the edge of the table. Next, pull the container in a quick, downward motion against the side of the table. The cap will click and release as you move it down against the edge. It is an effective way of how to open childproof caps.

For this method, you will be turning the container over on a flat surface. Use a table or a counter to press your palm down on the base of the inverted container. Apply only light pressure to the base. Then, rotate the bottle while keeping the lid motionless through friction. Try to hold the cover with your other hand, so it doesn’t move. Stop rotating once the cap clicks or releases. Then, you have to keep both the lid and container in your hand and turn both of them over. This way, you will lift the lid off and open the pill container.

Using a Bottle OpenerThis last method requires a bottle opener. You need to use one made of rubber and have non-slip grooves, to provide you with a good grip. This type of bottle opener is designed for individuals with limited arm mobility, as it only requires you to use your fingers or palm, and light pressure in opening a container. Place the bottle opener on the lid of the container and hold it in place with your other hand as much as possible. It will help if you have an extra rubber mat lying around to be placed under the bottle, so it remains secure, and you do not need to use your other hand to hold it in place. Use your fingers or palm to rotate the bottle opener. The firm grip of the opener rotates the container properly, allowing you to open it easily.

This type of bottle opener is designed for individuals with limited arm mobility, as it only requires you to use your fingers or palm, and light pressure in opening a container. Place the bottle opener on the lid of the container and hold it in place with your other hand as much as possible. It will help if you have an extra rubber mat lying around to be placed under the bottle, so it remains secure, and you do not need to use your other hand to hold it in place. Use your fingers or palm to rotate the bottle opener. The firm grip of the opener rotates the container properly, allowing you to open it easily.

Children naturally love to explore, and at times may place anything in their mouths. That is why childproof seals around pill bottle tops are provided to protect your medications and reduce the danger of your child from accidentally consuming what’s inside. But these cap designs are something that many adults and older adults struggle to open.

Child-resistant caps are necessary. You may find a childproof cap challenging to open, but it’s not impossible. You only need to learn the techniques on how to open childproof caps to assist you and put an end to that struggle. Know more about childproofing.

What to Know About Child-resistant Caps

May 15, 2022 Paul Green

Child-resistant caps are a life-saving invention found on most of today’s prescription and over-the-counter medications, cleaning chemicals, pesticides, and other toxic substances. For young parents, it feels like those tricky lids have been around forever, but they actually didn’t emerge until the late 1960s. What brought about the need for these preventative safety devices and why are they still so important today?

Who Invented Child-Resistant Caps?

The year 1967 in Canada was a bleak time for parents and their children. Without any child-resistant packaging to safeguard adult medications, children were swallowing prescription medicines at an alarming rate. In Canada alone in this era, more than 100,000 child poisoning cases were reported per year, resulting in at least 100 deaths.

In Canada alone in this era, more than 100,000 child poisoning cases were reported per year, resulting in at least 100 deaths.

Dr. Henri Breault was a concerned father of two and a pediatrician in Canada at the time who decided he had finally had enough of the tragedy. Determined to do something to prevent child poisonings, he designed a protective device called the Palm-N’-Turn. This mechanism was groundbreaking and quickly took the world by storm, eventually reducing child poisonings by 91%. Today, Dr. Breault is credited for innovating the first child-resistant cap.

Child-Resistant Cap Laws in the United States

Around the same time in the United States, where child poisonings were happening just as frequently, US Congress passed a law called the Poison Prevention Packaging Act (PPPA) of 1970. The Consumer Product Safety Commission (CPSC) was formed in 1972 “to protect the public against unreasonable risks of injury associated with consumer products”. They oversee the regulations for packaging dangerous household items. The act made it mandatory for industrial packagers to use the new child-resistant caps on all toxic chemicals, medicines, and other substances that could be deadly in the hands of a child.

They oversee the regulations for packaging dangerous household items. The act made it mandatory for industrial packagers to use the new child-resistant caps on all toxic chemicals, medicines, and other substances that could be deadly in the hands of a child.

As a result of this new law, poison-related child fatalities dropped by 90% nationwide.

When Is a Product Required to Have a Child-Resistant Cap?

Today, anything that is harmful when ingested — even if only in small doses — is required to have a child-resistant cap. Prescription and over-the-counter drugs, household chemicals, mouthwash, eye drops, nasal spray, insecticides, bleaches, and even vitamin supplements all fall under this umbrella.

How Do Child-Resistant Caps Work?

The CPSC has conducted testing on a variety of child-resistant cap designs and found success in a number of them, including:

- Pull rings: Remove the lid and peel back the protective layer using the pull ring.

- Squeeze-and-pull bottles: Pinch the sides of the lid as you pull the lid away from the container.

- Push screw caps: Push down on the lid and continue pushing down as you twist the cap to the left.

- Flip-off caps with arrows: Line up the arrow on the lid with the arrow on the bottle and flip it up to remove the cap.

- And other types also exist.

Most child-resistant lids are intuitive for their intended adult consumer to open, but if that’s not the case, there will usually be directions for opening the bottle listed on the cap or the bottle label. For example, push-and-twist caps often have the words “push down and turn” printed in an obvious place with arrows indicating which direction to twist the lid.

How Effective Are Child-Resistant Caps?

Keep in mind that child-resistant caps are designed merely to slow children down if they attempt to open a hazardous container. If chemicals and pharmaceuticals were completely child-proof , they would prove very difficult, if not impossible, for senior citizens to open. Thankfully, child-resistant lids buy parents a little more time to catch their children in the act before they ingest something dangerous.

Thankfully, child-resistant lids buy parents a little more time to catch their children in the act before they ingest something dangerous.

According to the PPPA, a child-resistant cap is effective when “designed or constructed to be significantly difficult for children under five years of age to open within a reasonable time, and not difficult for normal adults to use properly.” By the time a child reaches kindergarten, they’ll likely be able to open most child-resistant cap designs without any problems.

Why You Need Child-Resistant Packaging for Your Products

First and foremost is to insure the safety of kids. Second, industrial packaging companies are more likely to stay out of court when they comply with the PPPA. If you can manage to protect your consumer with child protective devices, you’ll avoid costly lawsuits while protecting kids and your business in the long run.

Why Choose Child Related Research for Your Child-Resistant Package Testing?

For over 50 years, Child Related Research (CRR) has forged its reputation as the worldwide leader in testing the efficacy and safety of child-resistant and senior-friendly packaging with a unique focus on the best turnaround time and client service in the industry.

At CRR, we help companies globally like yours determine whether or not your packaging complies with the US and/or International standards for child resistant and senior friendly packaging. To discuss your CR package testing needs contact us today at www.crr.net or call us at 801-904-3893.

Caps, Child Proof Caps, Child Resistant Caps

Push-turn lid packaging

The packaging is designed to store medicines, chemicals and similar products that are not suitable for children to come into contact with. Part of the body of the vial at the end opposite to its neck is made narrowed. The named part of the bottle and the outer surface of the cap have several oblique protrusions located along their lateral periphery. The oblique protrusions on the lid are inclined in the direction opposite to the direction of inclination of the vial protrusions. EFFECT: invention makes it possible to improve the convenience of using the package by facilitating its opening and closing. 4 w.p. f-ly, 1 tab., 5 ill. nine0003

4 w.p. f-ly, 1 tab., 5 ill. nine0003

The invention concerns packages containing a vial with a push-turn cap.

Push-turn covers are well known. Lids of this type are used to protect against children packages containing drugs, chemicals and similar products, contact with children is undesirable (see US patents N 3944102, 5020681).

The push-to-turn lid is child-resistant because the push-to-turn lid consists of two shells, an outer shell and an inner shell. The inner sheath is threaded to interact with the neck threads. The lid has means for engaging the outer shell with the inner one, as well as means for holding the shells in an unengaged position. nine0003

When the lid is in its original rolled position, the outer shell is depressed and does not interact with the inner lid shell because they are not interlocked, so the child can spin the outer shell of the closed lid to no avail without achieving rotation of the entire lid. In fact, in order to rotate the entire lid, you need to press on the outer shell of the lid, as if pushing it down. Then, without loosening the pressure on the lid, you should turn it, and the package will be opened. However, such manipulations with the lid are often difficult for adults, especially for the elderly. nine0003

In fact, in order to rotate the entire lid, you need to press on the outer shell of the lid, as if pushing it down. Then, without loosening the pressure on the lid, you should turn it, and the package will be opened. However, such manipulations with the lid are often difficult for adults, especially for the elderly. nine0003

The object of the invention is to provide a package with a push-turn lid that is easier for adults and especially the elderly to open and securely close.

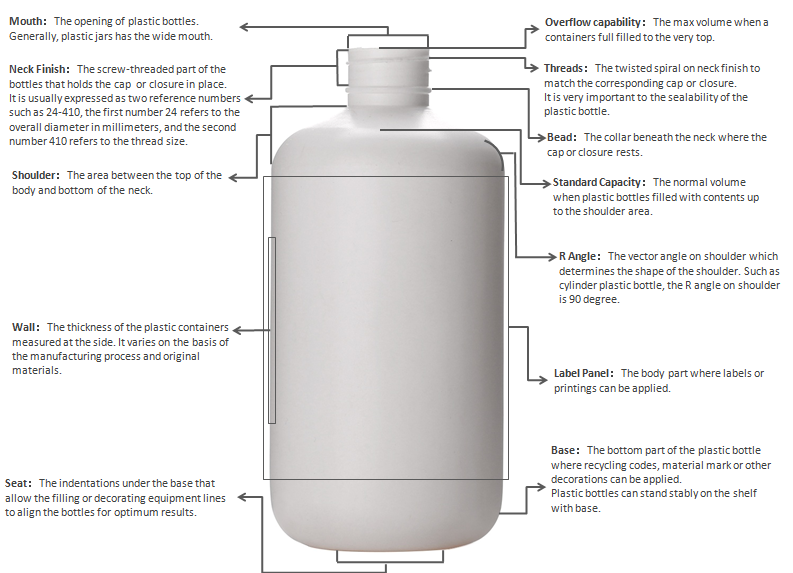

The problem is solved by the fact that a package with a push-turn cap of a known type, containing a bottle with a neck that limits the inlet at one end, and a body having an end opposite to the neck, and the neck has a thread, and the push-turn cap contains an inner shell with an internal thread for interacting with the thread of the neck and an outer shell made with the possibility of coupling the shells to each other, according to the invention, part of the body at its said end is made tapered, and this tapered part and the outer shell of the lid have several oblique protrusions located along their periphery, and the oblique protrusions on the lid are inclined in the direction opposite to the direction of inclination of the oblique protrusions on the vial. nine0003

nine0003

FIG. 1 shows a perspective view of a package according to the invention; in fig. 2 is a plan view of a package according to the invention; in fig. 3 is a side view of a package according to the invention; in fig. 4 is a bottom view of a package according to the invention; in fig. 5 is a side view of an open vial of the package.

The mentioned concerns of older people with opening push-to-turn lids lead many older people to choose to purchase unprotected packages, or to purposely degrade the security package by removing its feature that prevents children from opening it. The CPSC (Consumer Product Safety Commission) has published data indicating that the use of drugs intended for the elderly accounts for a significant percentage of child poisoning each year. (55 Fed. Reg. 40856, 5 Oct. 1990).

To address this issue, the CPSC has proposed a series of changes to the protocol tests for evaluating child-resistant packages (Fed. Reg. 5 Oct. 1990, 5 Mar. 1991, and 21 Mar. 1994). By changing the age of the reference population to 60-75 years and raising the entry criteria to 90%, child-resistant packaging provides better access for all adults.

Reg. 5 Oct. 1990, 5 Mar. 1991, and 21 Mar. 1994). By changing the age of the reference population to 60-75 years and raising the entry criteria to 90%, child-resistant packaging provides better access for all adults.

For example, the use of push-and-turn caps that cannot be opened by a child has been a longstanding problem for the elderly. Efforts to resolve this problem have focused primarily on the operation of the closure mechanism, without addressing user ergonomics or the external configuration of the package in order to improve closure performance. nine0003

Due to the presence of a plurality of protrusions around the perimeter of the outer part of the outer shell of the cap and around the perimeter of the bottom of the vial, the package according to the invention functions in an improved manner from an ergonomic point of view. It is easier for the elderly to open such a package at the initial opening and they can properly re-seal it, keeping it out of the reach of the child and the integrity of the product during its useful shelf life.

By reducing the difficulty experienced by the elderly when first opening the package, the invention also provides a high probability of correct use of the package, without spoiling or throwing away parts of the package that keep it out of reach of children. nine0003

Package 1 contains a cylindrical vial 2 and a push-and-turn cap 3. Vial 2 includes a body 8 with an opening 4, the neck 5 being vertically threaded adapted to the shape of the inner shell of the cap mechanism 3 described below. Those skilled in the art will appreciate that other bottle configurations, such as a polyhedron, may be used for the package body of the invention. The protrusion 7 connects the neck 5 with the cylindrical body 8. The bevel 9 leads to the narrowed part 10 of the bottle 2, at its end opposite the hole 4. Around the circumference of the narrowed part 10 of the vial 2 there are several beveled protrusions 11. Those skilled in the art will understand that such protrusions can alternate with smooth areas while still providing ample gripping surface. Alternatively, such protrusions can be located around the circumference of the cylindrical body 8 of the vial, and not in the narrowed part 10.

Alternatively, such protrusions can be located around the circumference of the cylindrical body 8 of the vial, and not in the narrowed part 10.

Each oblique projection 11 has a front surface 12, a "step" or edge 13 and a curved surface 14 to transition the front surface 12 and edge 13 into the bottom surface 20 of the vial. Those skilled in the art will recognize that other means may be used to form gripping points equivalent to the gripping points on the projections 11. Obviously, such alternative gripping means include raised or tangible reliefs or ridges. The tapered portion 10 has a length L sufficient to provide a sufficient gripping area corresponding to the size of an average adult's hand for most of the population, i.e. up to 9five%. The constricted portion 10 may be longer or shorter than shown in the drawing, however, it cannot be shortened so that the user cannot grasp the vial 2 by its bottom.

The lid 3 is a push-and-turn lid and has outer and inner shells that are engaged by push and turn. One skilled in the art will appreciate that any push-turn closure mechanism including an outer shell, an inner shell, and means for engaging the two shells by pressing and turning can be used for the improved packaging of the present invention. Examples of such mechanisms, their design, components, arrangement and operation of both the inner and outer shells, can be found in US Patents 4997096, 3055524, 3857505, 5020681, 3776407 and 4353474, the contents of which are incorporated into the present description by reference.

One skilled in the art will appreciate that any push-turn closure mechanism including an outer shell, an inner shell, and means for engaging the two shells by pressing and turning can be used for the improved packaging of the present invention. Examples of such mechanisms, their design, components, arrangement and operation of both the inner and outer shells, can be found in US Patents 4997096, 3055524, 3857505, 5020681, 3776407 and 4353474, the contents of which are incorporated into the present description by reference.

One preferred push-and-turn engagement means includes a series of vertical protrusions located around the circumference of the inner shell. These protrusions mate with a vertical element of a pointed wedge passing along the inner circumference of the outer shell. When a downward force is applied, the vertical member interacts with the vertical protrusion and a path is formed to allow removal of the cover. An exemplary other push-and-turn engagement means uses an engagement structure that locks together a vertical and an inclined surface, or two inclined surfaces. This allows both surfaces to slip if not enough downward force is applied. The higher the torque required to unscrew the cap, the greater must be the downward force required to engage the unscrewing mechanism. In addition, both parts do not rotate freely, so even more torque may be required to engage the child-resistant cap. Obviously, these and other equivalent push and turn mechanisms are within the scope of the present invention. It is also contemplated that certain child restraint mechanisms such as those specified in ASTM 3475 for Type I, Type II, and Type III packages, specifically Type I (continuous thread), including subtypes A&H (Push-Turn), B&C ( compression - turn), F&G (raise - turn). Type II (protruding finish), including subtype A (push-turn), and type III (snap closure), including subtype A (alignment and push up), are within the scope of the present invention. nine0003

This allows both surfaces to slip if not enough downward force is applied. The higher the torque required to unscrew the cap, the greater must be the downward force required to engage the unscrewing mechanism. In addition, both parts do not rotate freely, so even more torque may be required to engage the child-resistant cap. Obviously, these and other equivalent push and turn mechanisms are within the scope of the present invention. It is also contemplated that certain child restraint mechanisms such as those specified in ASTM 3475 for Type I, Type II, and Type III packages, specifically Type I (continuous thread), including subtypes A&H (Push-Turn), B&C ( compression - turn), F&G (raise - turn). Type II (protruding finish), including subtype A (push-turn), and type III (snap closure), including subtype A (alignment and push up), are within the scope of the present invention. nine0003

The outer shell of the cover 3 is provided with several protrusions 15 located around the circumference of the side of the cover. One skilled in the art will appreciate that such protrusions may also be interspersed with a smooth surface to provide sufficient gripping area. Each projection has a front surface 16, a corner or edge 17 and an arcuate transition surface 18 where the front surface 16 and edge 17 join to form the top surface 19 of the lid. One skilled in the art will recognize that other means may also be used to form gripping points equivalent to those found on the oblique projections 11. These other gripping means are contemplated to include raised or at least perceptible relief or ridges. It is desirable that the oblique protrusions on the cap 3 and on the constriction 10 of the vial face in opposite directions. Given this, it is preferable that the edge or edge surface 17 of the oblique projections 15 on the cap 3 be directed counterclockwise, and the edge or edge surface 13 of the oblique projections 11 on the bottle 2 be directed clockwise when viewed from above the bottle. nine0003

One skilled in the art will appreciate that such protrusions may also be interspersed with a smooth surface to provide sufficient gripping area. Each projection has a front surface 16, a corner or edge 17 and an arcuate transition surface 18 where the front surface 16 and edge 17 join to form the top surface 19 of the lid. One skilled in the art will recognize that other means may also be used to form gripping points equivalent to those found on the oblique projections 11. These other gripping means are contemplated to include raised or at least perceptible relief or ridges. It is desirable that the oblique protrusions on the cap 3 and on the constriction 10 of the vial face in opposite directions. Given this, it is preferable that the edge or edge surface 17 of the oblique projections 15 on the cap 3 be directed counterclockwise, and the edge or edge surface 13 of the oblique projections 11 on the bottle 2 be directed clockwise when viewed from above the bottle. nine0003

In evaluating the operation of the closure and how to assist a person in opening a package, it may seem that guiding the edge or edge of the sloped surfaces on the lid in the unscrewing direction (in the drawing, clockwise when viewed from above) would be most valuable. However, other factors, especially the automatic lid mechanism, make this configuration undesirable. In addition, when opening a push-turn cover, the opening mechanism is activated by pressure on the top of the cover with the palm of your hand, and not by squeezing the edges of the cover, as is the case when opening threaded covers. The unscrewing action is provided more by rotating the vial away from the cap than by turning the cap itself. In the narrowed part of the vial, the edges of the protrusions are directed clockwise (when viewed from above), providing a gripping area when turning the vial to open it. When the package is closed again, the lid is grasped from the sides and twisted with fingers to tighten it on the vial. The edges of the oblique protrusions on the cover are directed counterclockwise (when viewed from above) to facilitate the closing process. The different direction of the oblique projections on the cap and vial provide the hand with improved force transmission through a series of grip points that focus the opening and closing forces both clockwise and counterclockwise.

However, other factors, especially the automatic lid mechanism, make this configuration undesirable. In addition, when opening a push-turn cover, the opening mechanism is activated by pressure on the top of the cover with the palm of your hand, and not by squeezing the edges of the cover, as is the case when opening threaded covers. The unscrewing action is provided more by rotating the vial away from the cap than by turning the cap itself. In the narrowed part of the vial, the edges of the protrusions are directed clockwise (when viewed from above), providing a gripping area when turning the vial to open it. When the package is closed again, the lid is grasped from the sides and twisted with fingers to tighten it on the vial. The edges of the oblique protrusions on the cover are directed counterclockwise (when viewed from above) to facilitate the closing process. The different direction of the oblique projections on the cap and vial provide the hand with improved force transmission through a series of grip points that focus the opening and closing forces both clockwise and counterclockwise. nine0003

nine0003

According to the present invention, the improved packaging shown in FIG. 1, provided with a plurality of oblique projections located around the circumference of the side outer shell of the cap and directed counterclockwise (when viewed from above), and a plurality of oblique projections directed clockwise (when viewed from above) around the circumference of the narrowed part in the lower part of the cylindrical body of the vial was subjected to a comparative test for its use by the elderly under the protocol for child-resistant packs, together with a pack with a standard push-turn cap and vial of the same size and with the same push-and-turn mechanism, but without oblique protrusions on the cap and on the vial. A commercial push and turn mechanism from Plastics Corp. was used. called FG. The package according to the invention is called "package with oblique projections", and the standard package without such sections is called "regular package". nine0003

nine0003

Two hundred elderly people who participated in the trials were divided into two separate groups of 100 participants each according to the protocol below. In order to avoid subjective assessments, participants were asked to open the regular or slanted tab packaging first, without prioritizing when distributing to all 100 participants of a certain age and gender per package. Each participant received one package and was given 5 minutes to open it and close it again. After 5 minutes, or when the first package was opened and closed, the first package was taken away and the participant was given a second package of the same type to open and reclose within 1 minute already. The same procedure was repeated with another type of package. The amount of time spent opening-closing both the first and the second type of package was recorded. Participants were then asked about their preference between the two types of packaging and were asked to rate both types on a scale of 1 to 10, with 1 being the lowest and 10 being the highest. nine0003

All testing work and data collection was performed by an independent laboratory commissioned by the Consumer Food Safety Commission (CPSC). Testing was conducted in accordance with protocols for the elderly and children as published in Federal Handbook, vol. 56, No. 43, March 5, 1991 and Federal Handbook, vol. 69, No. 054, March 21, 1994.

Time data spent on opening, and the survey results were analyzed for statistical significance. Opening times were analyzed using a non-parametric value test (see, for example, the book "Non-parametric Statistical Methods". Hollander and Woolf. 1973, Wiley). As usual, the equal score (coincidence of grades and time) was ignored.

All results below are statistically significant at the 5% level (p-value less than or equal to 0.05) unless otherwise noted. This means that there is a small probability, not exceeding 5%, that the results obtained are due to natural variations and not to a real effect. The lower the "p" value, the lower the chance that the results are due to natural variations. Empirical data (opening time) and subjective data (evaluation) show a statistically significant improvement in the technical performance (actual and felt) of the beveled package compared to the conventional package as measured. nine0003

When comparing the times of the first and second openings separately, it is found that it takes longer to open a conventional package than to open a sloped package (p-value less than .001).

Results from a group of elderly people: average opening time, s: regular package - 10.08 oblique tab package - 8.51 average spread of opening times, s: regular package - 6.00 oblique tab package - 4 .00 Five participants failed to open the regular slanted tab package (on their first attempt), which yields a statistically significant difference (p-value of .03). One person failed to open the slanted packaging on the second attempt, but of those who successfully opened the regular packaging on the first attempt, three failed to open the regular packaging on the second attempt, making a non-statistically significant difference (p-value of . 30) . The difference in failures to open the package (see table) was tested, due to the low number of failures, by means of an exact test of binomial proportions, see, for example, appendix 1 (31) in the book "Quality Control and Industrial Statistics", 4th de , by Duncan (1974, Irvine).

30) . The difference in failures to open the package (see table) was tested, due to the low number of failures, by means of an exact test of binomial proportions, see, for example, appendix 1 (31) in the book "Quality Control and Industrial Statistics", 4th de , by Duncan (1974, Irvine).

Each participant was asked to rate both packages on a ten-point scale from 1 to 10. The oblique tab package scored higher than the regular package (p-value less than .01). Of the 200 participants, 141 rated the packages differently, of which 107 participants gave a higher rating to the slanted tab packaging. These data were analyzed using the non-parametric value test mentioned above.

In addition to the rating data, each participant was asked to express their preference between the regular and slanted tabs (or no preference) regarding their appearance, operation, and overall rating. Of those who expressed a preference, more than 50% preferred the slanted tab package over the regular package in all three dimensions. For this analysis, the standard construction method 9 was used.5% CI for binomial proportion.

For this analysis, the standard construction method 9 was used.5% CI for binomial proportion.

According to the protocol of the Federal Directory, Vol. 59, No. 054, March 21, 1994, a large size package according to the invention was tested with a calculated efficiency of 100% obtained for the elderly.

Claim

1. A package with a push-turn cap containing a vial with a threaded neck limiting the inlet at one end and a body having an end opposite to the neck, characterized in that the part of the body at its said end is narrowed, moreover, this narrowed part and the outer surface of the cap have several oblique projections located along their lateral periphery, and the oblique projections on the cap are inclined in the direction opposite to the direction of inclination of the oblique projections on the narrowed part of the vial. nine0003

2. Packaging according to claim 1, characterized in that the oblique projections on the cap are directed counterclockwise, and the oblique projections on the vial are directed clockwise.

3. Packaging according to claim 1, characterized in that the vial has a cylindrical shape.

4. Packaging according to claim 1, characterized in that the oblique projections completely cover the perimeter of the vial and cap.

5. Packaging according to claim 1, characterized in that the oblique projections are located intermittently around the perimeter of the vial and cap. nine0003

PICTURES

Picture 1, Picture 2, Picture 3, Picture 4, Picture 5, Picture 6

How do I open this damn bottle????

how to open this …

#1

#2

#3

Guest

You may need to press hard on the cover and turn it.