Instrument used to break water

A Guide to Delivery Room Labor Tools

Don’t be alarmed when you see a nurse don a sterile hat, mask and gloves—all it means is that you’re getting close to delivery and it’s time to set up the doctor’s table. But some of the standard labor tools might not look so familiar to you. To help you mentally prepare, here’s a breakdown of the medical tools you might spot being set up. There’s a lot you can’t control during birth, but hey, at least you can know what’s being used and why.

1

Image: Jenny Tod

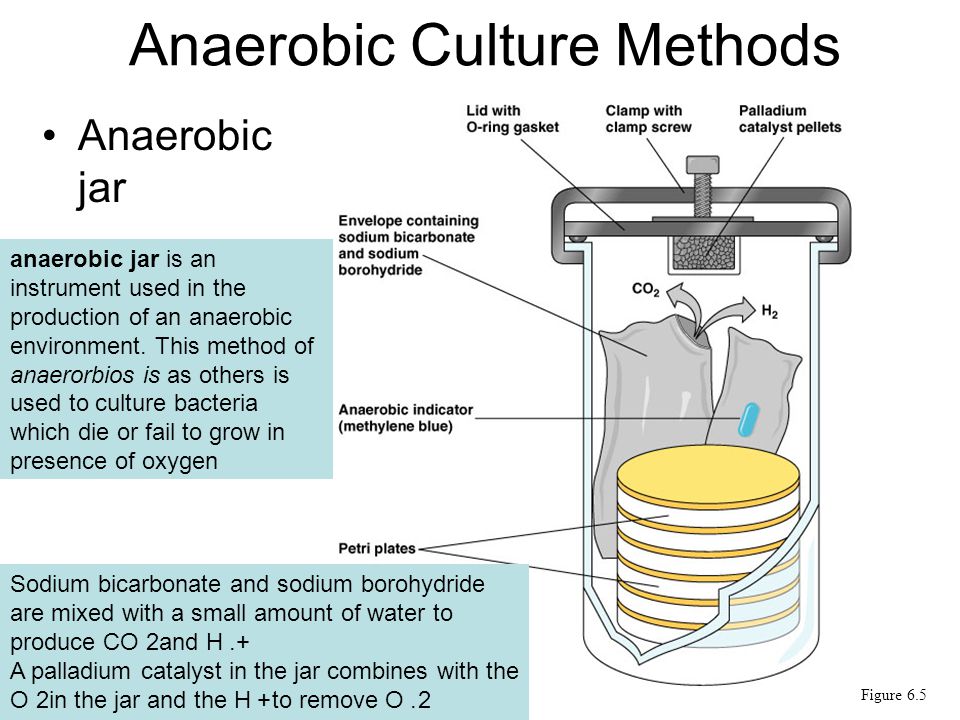

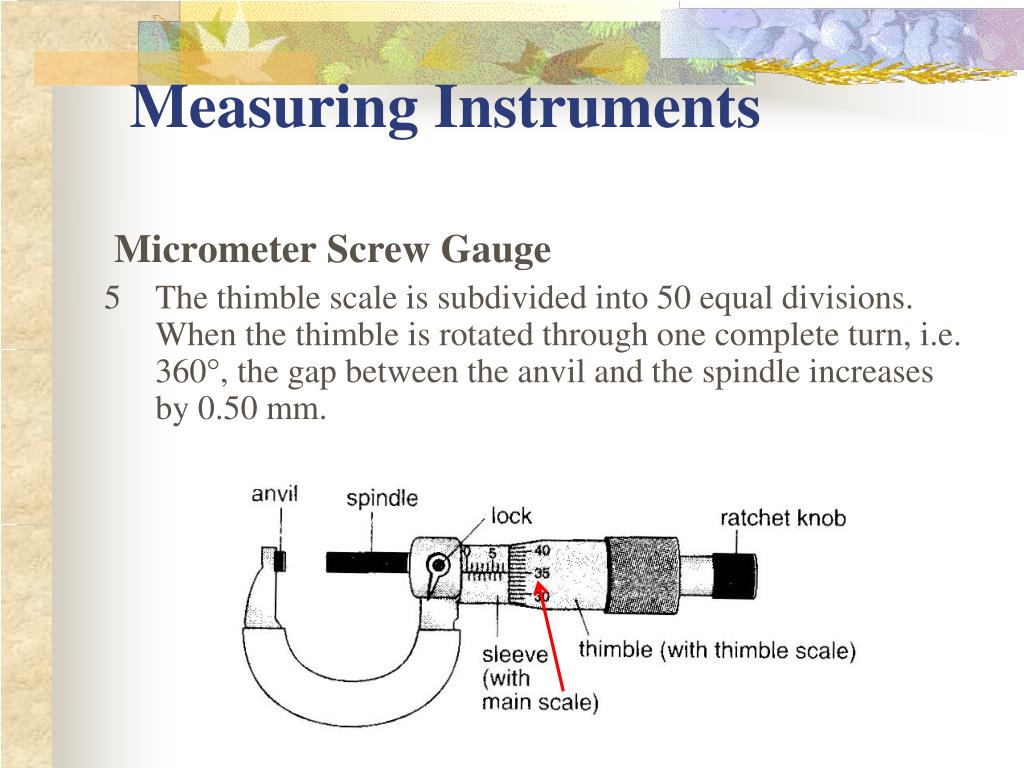

Amniotic hook

This long crochet-like hook is used in the early stages of delivery to break your water, otherwise known as rupturing the membrnaes, if it hasn’t naturally happened on its own. To break your water, the doctor will insert the amniotic hook and use it to puncture the amniotic sac. You might feel some slight discomfort as the device enters your vagina, but as for the actual water breaking, most women only feel a big, warm gush of liquid.

2

Image: Jenny Tod

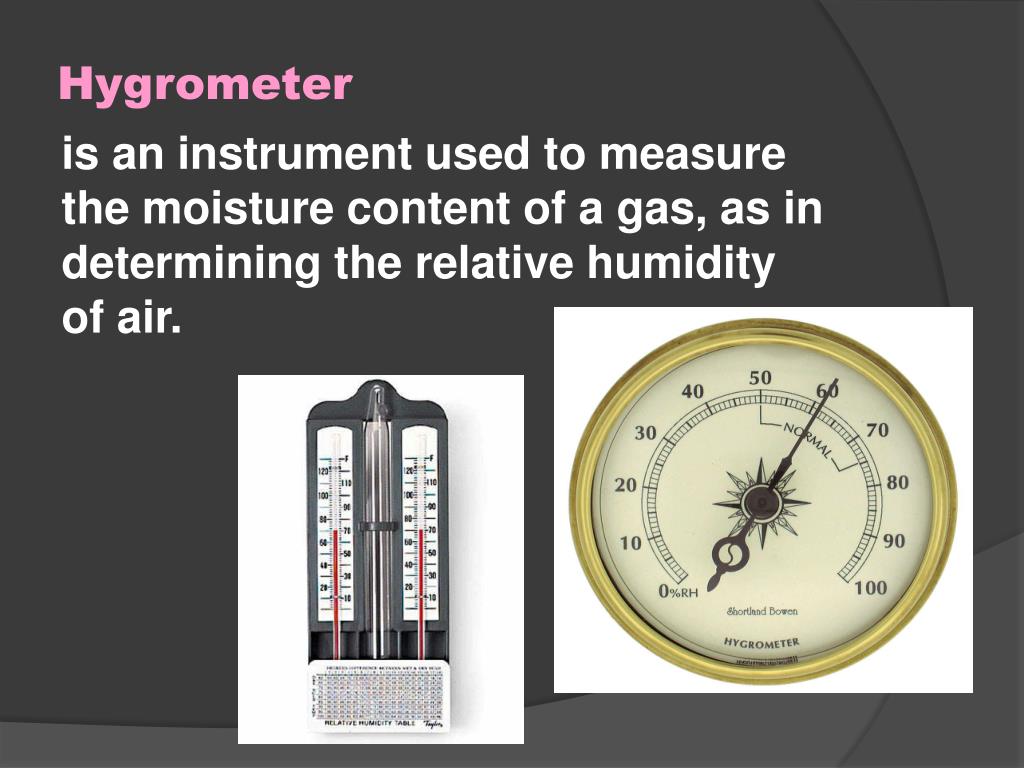

Speculum

This old friend (think back to all those gynecological exams) is used early in delivery to open your vagina and get a better look at your cervix to see how dilation and effacement are coming along.

3

Image: Jenny Tod

Forceps

Resembling large salad tongs, forceps are generally used if baby needs some help making her way through the last part of the birth canal, or if mom’s been pushing for a while and needs an assist. The forcep ends are curved to fit snugly (but not tightly) around baby’s head and gently pull her out as mom pushes.

4

Image: Jenny Tod

Vacuum

An alternative to forceps for an assisted delivery, a vaccuum extractor can help deliver baby through the use of suction. A small suction cup is attached to the top of baby’s head and pulls as mom pushes. Don’t be alarmed if baby comes out looking a little conehead-like—newborns’ heads are super-soft and pliable, and in a few days baby’s noggin will regain its normal shape.

5

Image: Jenny Tod

Scissors

You’ll likely catch sight of a couple different pairs of scissors in the delivery room. One pair will be used to cut baby’s umbilical cord. Another will be used if you need an episiotomy. In that case, your doctor will have to cut into the perineum (the skin between the vagina and anus) to help baby fit through. The good news is, episiotomies aren’t very common these days.

In that case, your doctor will have to cut into the perineum (the skin between the vagina and anus) to help baby fit through. The good news is, episiotomies aren’t very common these days.

6

Image: Jenny Tod

Hemostat

This clamp may look a lot like a pair of scissors, but it doesn’t have the same sharp blades. Instead of cutting, it’s used to contain any bleeds, hold sutures and—most importantly—clamp the umbilical cord before it’s cut.

7

Image: Jenny Tod

Sponge Holders

To keep any bleeding during delivery under control, your doctor may apply pressure with highly absorbent laparoscopic sponges. She’ll use sponge holders—ringed tools that look sort of like forceps—to keep a grasp on the gauzy sponge.

8

Image: Jenny Tod

Scalpel

Unless you’re having a c-section, your doctor probably won’t use this—but it may be kept on hand.

Please note: The Bump and the materials and information it contains are not intended to, and do not constitute, medical or other health advice or diagnosis and should not be used as such. You should always consult with a qualified physician or health professional about your specific circumstances.

You should always consult with a qualified physician or health professional about your specific circumstances.

save article

Your Pregnancy Week by Week Guide

Loading...

Next on Your Reading List

How can you get your water to break and is it safe?

Women can get their water to break with the help of a doctor, but it is not safe for them to attempt to break their water at home.

However, there are many natural methods that women can use to encourage labor to begin once the pregnancy has reached full term.

In this article, we cover the risks of breaking your water and provide alternative ways to induce labor safely.

Share on PinterestIt can be dangerous for a woman to try and break her water at home before natural labor begins.There are no proven safe ways for a woman to break her water at home. It can be dangerous if the water breaks before natural labor begins or before the baby is fully developed.![]()

During the natural process of labor, the water breaks when the baby’s head puts pressure on the amniotic sac, causing it to rupture. Women will notice either a gush or a trickle of water coming out of the vagina.

Many doctors say that women must give birth within 12–24 hours of the water breaking. After this time, a doctor may recommend a cesarean delivery to ensure the safety of the woman and the baby.

This is because it is easier for bacteria to get into the uterus after the water breaks. This increases the risk of infection, which is a major complication that puts both the woman and the baby at risk. It may also make the birth more difficult.

It is particularly dangerous to use artificial instruments to rupture the amniotic sac, as this can introduce bacteria into the uterus and cause infections. It could also injure the baby.

Labor can begin without the water breaking. As a result, women can speed up or induce labor naturally without breaking their water.

Share on PinterestA doctor can use a procedure called an amniotomy to break a woman’s water.

In some cases, a doctor can help a woman’s water to break using a procedure called an amniotomy. They will insert a device into the vagina and very carefully use it to break the amniotic sac.

Before carrying out an amniotomy, the doctor will ensure that the baby is head-down and that the procedure is safe for both the woman and the baby.

Most women will not need an amniotomy to induce labor. However, it is usually safe and provides an alternative or additional option to using medication.

An amniotomy may not be safe for every woman. The American College of Obstetricians and Gynecologists (ACOG) recommend against a woman having an amniotomy when her labor is progressing normally, and the baby appears to be in good health.

Apart from an amniotomy, doctors can induce labor by using a catheter to dilate the cervix or by prescribing medication, such as Pitocin.

The World Health Organization (WHO) say that attempts to induce labor may be harmful if there are no medical reasons to justify them. This includes efforts to speed up the water breaking.

This includes efforts to speed up the water breaking.

Allowing a woman to go into labor naturally can lower the risk of complications and minimize the likelihood of unwanted labor interventions, such as cesarean deliveries.

Women whose doctors recommend breaking their water should ask questions about the risks and benefits and get clear details about how this might affect their options during labor.

Any intervention to induce labor will present benefits and risks. For some people, the risks of remaining pregnant may be greater than the risks of inducing labor. For others, it is safer to wait.

It is essential to discuss each pregnancy with a doctor to determine the best course of action.

The end of pregnancy can be exhausting. People believe that there are many ways to induce labor, from eating spicy food to going for long walks.

There is little evidence to support most of these ideas. However, the following methods may safely help to induce labor, if the woman’s body is ready.

Women should only consider using these techniques to encourage the natural onset of labor once the pregnancy has reached full term. They should also confirm first with a doctor that their pregnancy is low risk.

Have sex

Having sex, particularly vaginal penetration, may help to start labor. It is not clear whether this is due to hormonal changes, physical stimulation, or something else.

A 2014 study found a link between having sex during the last week of pregnancy and going into labor. Women whose water has already broken should not have sex as this can increase the risk of infection.

Try nipple stimulation

Nipple stimulation may be a natural way to get the body to release oxytocin, a hormone that plays a key role in both labor and breast-feeding.

Learn more about how nipple stimulation can induce labor.

Eat some dates

A small 2011 study asked women to eat six dates per day during the last 4 weeks of their pregnancy.

The researchers found that 96 percent of the women who ate dates had spontaneous labor, compared to 79 percent of those who did not. The women who ate dates also had greater dilation of their cervix during labor.

The women who ate dates also had greater dilation of their cervix during labor.

Share on PinterestHaving sex may help to induce labor.

The risks of inducing labor at home depend on the chosen method.

Natural methods that do not expose the baby to new chemicals tend to be the safest. These include having sex or stimulating the nipples.

Nutritional and herbal remedies can be dangerous, especially if a woman eats large quantities of herbs or is not aware of the possible side effects.

Any food that a woman consumes during labor can affect the baby, so it is essential to talk to a doctor before trying any herbal or dietary remedies.

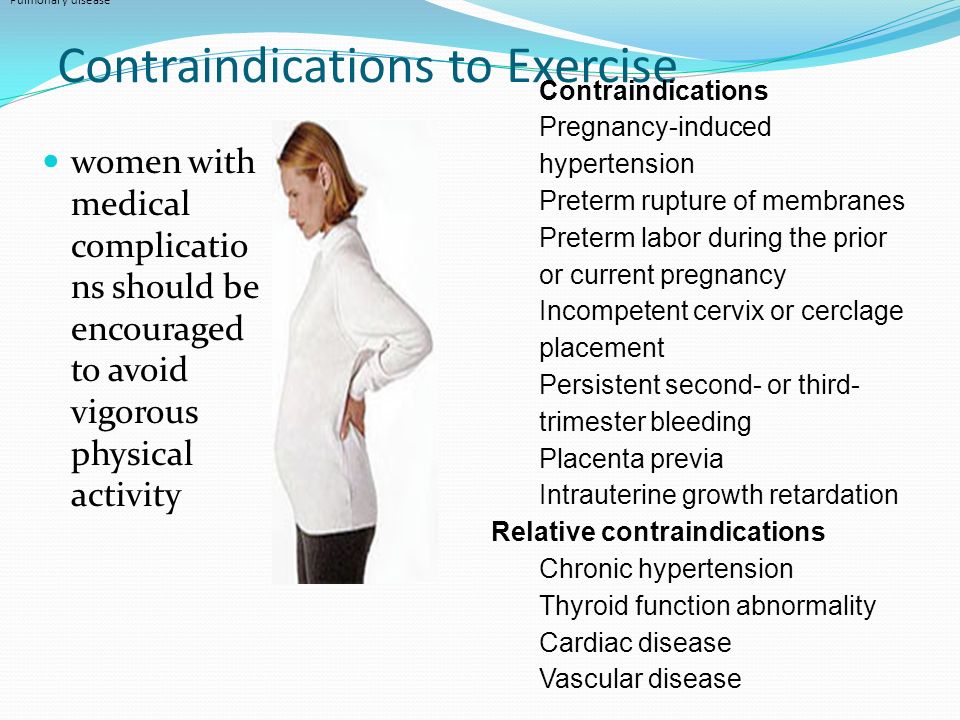

Some women try to induce labor with intense physical activity, such as playing a sport. Exercise is generally safe during pregnancy, although there is little evidence to suggest that it can induce labor.

Women who have not exercised during their pregnancy should not begin an intense exercise regimen at this late stage. It is also vital to avoid falling or doing anything that could impact on the abdomen.

The last few weeks of pregnancy can be challenging. Many women who are giving birth for the first time will go past their due date. This may be worrying, but it is common and is not likely to harm the baby.

Almost all women eventually go into labor on their own. While the waiting can be tough, it is generally safest to wait for the natural onset of labor. A doctor will be able to provide advice for each individual.

Women with specific risk factors, such as hypertension or gestational diabetes, may need a doctor to induce their labor.

Women may also need a labor induction if there are any signs that the baby is distressed. In such cases, inducing labor safely may increase the likelihood of vaginal birth and a healthy baby.

Women should discuss their concerns with their doctor and ask them to explain the benefits and risks of each option. Women should also be aware of what to expect during the onset of labor, and how to get hold of their doctor if they suspect that they might be in labor.

what it is, types and characteristics © Geostart

Heading: Tools and equipment

Chisel: what it is, types and characteristics

Chisel is a term that combines a slotting tool widely used in joinery and carpentry, as well as in drilling wells for the extraction of gas, oil and artesian water.

What is it?

Archaeologists during excavations of ancient mounds and cities quite often find the remains of ancient wooden utensils, which directly indicates that our ancient ancestors mastered the art of woodworking to perfection. In Rus', all buildings and the entire arsenal of household utensils, from the simplest furniture to tools, were originally made of wood. With the development of technology, the manufactured objects of labor and everyday life were updated more and more elegant, and all because the craftsmen managed to create various effective tools, among which the chisel played the most important role. This tool is relevant in our time, including the one that has practically remained in its original form.

This tool is relevant in our time, including the one that has practically remained in its original form.

The chisel is a simple tool that is indispensable for gouging small holes, spikes and sockets during roughing wood, as well as for trimming wooden blanks to the desired shape. This is a steel bar of a square or rectangular shape, slightly tapering towards the sharpened end. Tool sharpening is usually one-sided.

The chisel is distinguished by a fairly tight fixation of the cutting part shank in the handle. The strength of this fastening is due to the cap with a sealed neck, which allows you to transfer a fairly large force. When processing wood, the chisel is subjected to high loads, since the gouging of recesses in solid bases is accompanied by sharp blows of the mallet on the handle, which is why the handle is made either from hardwood or from polymers with high hardness. If the handle is made of wood, it is additionally reinforced with a metal ring, which increases the strength of the part and prevents the material from cracking.

Less common is a chisel with a semi-circular base - such a tool is indispensable for cutting grooves, as well as cleaning the corners of the workpiece. And also on sale you can find U-shaped canvases, which are optimal for forming recesses for door hinges.

Types and features

Depending on the size of the tool and the shape of the cutting blade, the chisel can be used for a wide variety of woodworking jobs. The chisel blade can be square, semicircular with different diameters, peaked, sharp, and even similar to a drill. According to the features of operation, the classification includes milling, electric, pneumatic and manual models used in construction and carpentry.

So, a beveled chisel has a trapezoidal blade, the blade is elongated, the edge is beveled. This tool is indispensable for knocking out grooves with right angles and even edges, it is used for processing corner parts. The blade has a long bevel, thanks to which the tool can penetrate into the most inaccessible places where any other types of tool cannot go. With the help of a semicircular chisel, fibers are sampled from the inside of the deck; such tools are very similar in appearance and functionality to a chisel.

With the help of a semicircular chisel, fibers are sampled from the inside of the deck; such tools are very similar in appearance and functionality to a chisel.

The tapered chisel is unlike any other - its blade is longer and thinner, and the cutting edge is much more beveled. The shape, as a rule, is rectangular, such tools are optimal for stripping after processing with a carpenter's chisel. Mini chisel, as the name implies, is the smallest model that is suitable for fine and delicate work. The L-shaped chisel is widespread - it is used for knocking out grooves, as well as square holes for mounting fittings and forming straight edges in wooden blanks.

The long chisel has found its use in carrying out work related to the need to penetrate into the material , its distinctive feature is a flexible and long blade. Hand-held tools include a slick - this is a rather large chisel, the blade of which reaches 60 cm in length and approaches 10 cm in width. Such models are quite heavy, so physical effort is required to work with it. Slick is used in rough carpentry and shipbuilding.

Such models are quite heavy, so physical effort is required to work with it. Slick is used in rough carpentry and shipbuilding.

Wide blade tool good for general construction and repair work , it is used for removing parquet boards, screeds and paintwork. Varieties of beveled chisels have a pointed oblique edge, usually sharpened at an angle of 45-60 degrees, while the blade can be sharpened in any direction. The most popular types of chisels are carpentry and joinery.

Carpentry

Carpentry is also called flat and thick, it is widely used among craftsmen whose activities are related to wood processing. Such a tool has a rather dense working blade, and the blade has a rectangular or square profile. The blade is characterized by increased strength, so they are popular for work that requires significant physical effort.

Carpentry

Carpentry chisel is a hand tool. It is performed with plastic or wooden handles, while the holders can be both removable and non-removable - the change, as a rule, is made in order to change the nature of the blow - with a mallet, hammer, hand. The cutter in most models is rectangular - it is quite convenient for them to carry out the most simple manipulations to create grooves and small nests in a tree. Slightly less common are models with a semicircle blade - they are suitable for chasing small grooves and cleaning corners.

The cutter in most models is rectangular - it is quite convenient for them to carry out the most simple manipulations to create grooves and small nests in a tree. Slightly less common are models with a semicircle blade - they are suitable for chasing small grooves and cleaning corners.

The working edge has a special sharpening, which determines the degree of mechanical impact. The blade is made of tool steel, the most expensive models are additionally hardened and anti-corrosion treated.

Special attention should be paid to the chisel for drilling, which differs significantly from joinery. Let's start with the fact that the pick for wells is a rather complex nozzle in its design, which is completed with a set of spherical and cylindrical segments made of high-strength alloys. The most technologically advanced models include bearing mechanisms, due to which, when colliding with rocks, the movement of the segments continues. Such a device is compatible with drilling rigs, impact rotary machines and aggregates for vertical excavation. The drilling tool has a rather complex device and larger dimensions than a carpentry tool - it is used to break hard and soft rocks, as well as dense soil.

The drilling tool has a rather complex device and larger dimensions than a carpentry tool - it is used to break hard and soft rocks, as well as dense soil.

Comparison with other tools

Many beginners confuse the chisel with some other tools - most often with a chisel. The product is a manual device with a grooved or flat shape of the cutting blade. The length of the blade varies from 4 to 40 mm, most often joiners and carpenters use several chisels in turn in their work.

Chisel and chisel are similar, but the main difference here is the steel used - thinner is chosen for the chisel, since this tool is designed to perform delicate operations. While the chisel is used for grooving. Steel in chisels is denser - this is the only way to ensure accurate cutting of the material. If the tool turns out to be blunt, then it will break the wood fibers and the surface of the workpiece will turn out to be rough and uneven, requiring refinement.

The handle of the chisel features an easy-to-press dome shape.

It cannot be used to strike - otherwise the handle will simply shatter into small pieces.

The chisel works as a result of the application of mechanical force of the impact type - in other words, it is hit with a hammer or mallet, which is why the handle is equipped with a crimp ring. The chisel is used exclusively by hand. The chisel looks very similar to a chisel, their principle of operation is similar, but the chisel is used for woodworking, and with the help of a chisel they work with concrete, metal and stone - this causes some design differences between the tools.

Highlights of choice

The chisel is an indispensable tool when cutting corner cuts, as well as when creating a wide variety of recesses. And since physical efforts are applied to it, the design of a high-quality tool should be appropriate - the blade width should not be less than 35-40 mm.

Keep in mind that a chisel is a tool with a wooden handle and a high impact force is applied to it, so despite the presence of a ring, the handle is often prone to cracking and as the material wears out, the risk that the handle will split and injure the worker increases . That is why it is better to give preference to those instruments in which this part is made of the most durable types of wood - oak, hornbeam or maple.

That is why it is better to give preference to those instruments in which this part is made of the most durable types of wood - oak, hornbeam or maple.

Pay special attention to the metal from which the blade is made. Steel must be tool steel that has undergone additional hardening, and also coated with anti-corrosion compounds. Otherwise, the tool will quickly become dull and break. If possible, test the tool at the time of purchase. For example, choose one that is "handy" - remember that you will have to hold it under a hail of blows, so it must be securely fixed in your hand.

Be sure to find out how the blade is attached to the handle. The cheapest models are shank connected - they are comfortable to grip, but the shank of the handle acts as a kind of wedge, which leads to loosening of the fastener. Over time, the handle may split or fly off the shank during work. In addition, purchase a tool from a reputable outlet and make sure that the bit meets all GOST requirements.

| author Kozina Taisiya |

Drilling tool for drilling water wells

When deciding on the arrangement of a well in your area, you need to decide on the equipment that will be required for this. And although professional specialists always have a tool for drilling, it is much cheaper to cope with the task on their own. Therefore, it is worth figuring out what is needed to create your own well, and what you can refuse without harming the entire enterprise.

Content

- What is included in the main list of drilling tools

- Book spoon

- BUP and a coil of spiral type

- LOVNOK

- Broken rifles

907 BURNING BURCHINGS -

What is included in the main list of drilling tools

For craftsmen, it will not be difficult to make some drilling tools on their own, and buy everything else in the store, especially since many of the design components are freely available.

You can use professional drilling rigs, but only in the case when a very deep well breaks under water. The use of attachments on sandy or light soils is not particularly necessary.

You can use professional drilling rigs, but only in the case when a very deep well breaks under water. The use of attachments on sandy or light soils is not particularly necessary. But if we are talking, for example, about stony soils, then cutters will definitely come in handy. These are elements that not only facilitate the penetration of the soil to the desired depth, but also provide flushing of the well shaft.

Various types of expanders are also used depending on the purpose of the well: not only the depth is needed, but also the width - it is necessary to use expanders, in all other cases this equipment is not needed.

Drill spoon

Used to work on soils of the following characteristics:

BC 1xBet has released an application, now you can officially download 1xBet for Android by clicking on the active link for free and without any registration.

- Clay, loam;

- Wet sand;

- Sand with stony, gravel or pebble elements.

Features of the drill spoon in its movements: translational or rotational. Representing a cylindrical device, the spoon consists of the following elements:

- crown or socket fitted with a thread the diameter of which matches the diameter of the stem used to wind the crown;

- cutting edge;

- a body or body provided with a longitudinal slit, one edge of which is concave inwards and the other sharply sharpened.

Getting inside during drilling, the soil accumulates in the shaft and remains until complete extraction. Therefore, it is important to choose the diameter of the drill spoon corresponding to the diameter of the installed pipe: 70, 140, 198 mm, taking into account the difference of 10 mm (the spoon should be smaller).

Drill and coil

The tool is indicated for use on clay soils, loams, sand and gravel mixtures. With increased strength, the design has the following device:

- threaded head or bit for mounting rod;

- spiral type coil equipped with a blade at the end.

The device has a lot of advantages, it makes it easier to cut the layers of the earth and at the same time strengthens the walls of the well, preventing them from collapsing. Gradually removing the soil, the spiral coil raises the rock up in turns, but it is necessary to release the tool from the soil in a timely manner by extracting the coil to the surface.

Bailer

Serves for lifting soil masses to the surface and is used on loose and loose soils. The bailer can be made with your own hands, if there is a material of increased strength. And if an individual accessory is required, then it can be easily made in a locksmith's workshop. Even with all the costs, such a device will be cheaper than buying it in a special store. What the bailer consists of:

- a piece of steel pipe, the diameter of which is determined based on the diameter of the water wells required;

- the lower end of the pipe is equipped with a cutting shoe - this is a hardened steel ring with a blade that cuts soil layers, acts as a crown;

- fixation of soil masses inside is provided by a special valve, which also needs to be made at the bottom of the pipe.

After the bailer rises, the valve opens and the body of the structure is freed from the ground.

After the bailer rises, the valve opens and the body of the structure is freed from the ground.

Important! When working on floating soils, it is necessary to use hip or lancet valves.

Impact or rotary bars

This is a mandatory element of the drilling design. Representing especially strong rod pipes, the design is able to withstand huge loads and various compressions, bends, stretching and twisting of metal during the operation of the drilling rig. If there is no pipe, then you need to take steel bars of square or round section to create a structure, and you can also install pipes used for water supply networks, where the wall has significant reinforcement.

Rotary drilling tools

The rotary drilling method, which involves cutting into the structure under pressure, requires a swivel, which is equipped with a rotor, a mud pump and a hose. If it is necessary to ensure rotational movements of the bit along the body of the mine, additional downhole screw motors are needed, designed for drilling wells under water.

An important role in this equipment is played by the rotors, which transmit the rotational movements of the entire structure. For these purposes, it is possible to use a winch, but this is not always necessary - there are rotors that can work individually.

The essence of a swivel in a water drilling rig is to ensure the connection of the drill string and the hoist system. As a result, a chain of rotation is created, where all the components of the drill are involved, while additionally, a flushing solution is delivered to facilitate work. But to connect the device to the tools, you need to install an adapter. Water is supplied under pressure through a flexible hose. For relief, a pump is used to pump fluid into the hoses. Natural pressure fluctuations during liquid supply are minimized by compensation installations mounted directly on the pump.

Drill Rig Options

It is worth revisiting the options for drilling rigs that determine how to drill a well under water and the application of various elements described above.

Remember that massive structures are most often equipped with diesel, electric or gas turbine drives. So, a hand drill for wells, varieties:

Remember that massive structures are most often equipped with diesel, electric or gas turbine drives. So, a hand drill for wells, varieties: - Screw. The cutting of soil layers is carried out by means of plates welded to the base of the drill. To work on difficult soils, diamond crowns are used.

- The core drill has the form of a pipe and a crown located at the bottom of the drill. The crown is made of durable metal cutters, sharpened, but you can purchase a finished item. For drilling especially strong layers, bits are needed.

- Percussion-rope drilling tool equipped with a bailer. It is used for punching wells under water in semi-loose and loose soils.

- Spoon drill equipped with a cutting edge along the bottom of the cylinder. Ideal for drilling wells under water in wet and non-caving soils. When installing the structure, it is necessary to carefully calculate the diameter of the spoon, but the length often does not exceed 70-100 cm.

- The coil is used for drilling loam, clay and gravel soil layers.

It has the feature of strengthening the walls of the shaft during drilling, often equipped with a diamond core bit to enhance penetration functions.

It has the feature of strengthening the walls of the shaft during drilling, often equipped with a diamond core bit to enhance penetration functions.

Important! Serpentine work is carried out rather slowly, but this is the simplest and most convenient tool for punching holes in difficult soils.

- Chisel chisel is used for drilling dry soils of loose sand or clay type. The tool is made from a single piece of viscous steel. Drill diameter: 7.4; 10.8; 14.7 cm. Chisels are an ideal replacement for diamond drill bits, which are used to break small stones.

- Rod drills are used where a percussive-rotary movement is required.

Existing diamond bits used for drilling in particularly hard rocks. A diamond drill can be electric or hydraulic, and it is possible and necessary to drill small wells for a well with a power tool, but hydraulics are more suitable for volumetric holes. Being especially durable, it is not always profitable to use a diamond drill for drilling wells, however, the advantage of significantly facilitating work with minimal manual effort outweighs the significant financial costs.